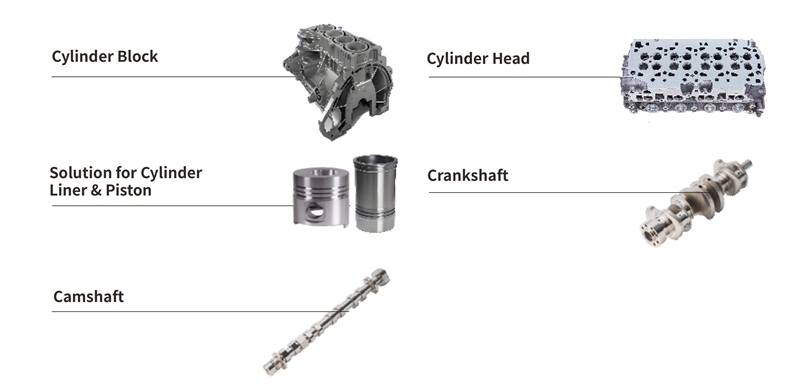

Engine system

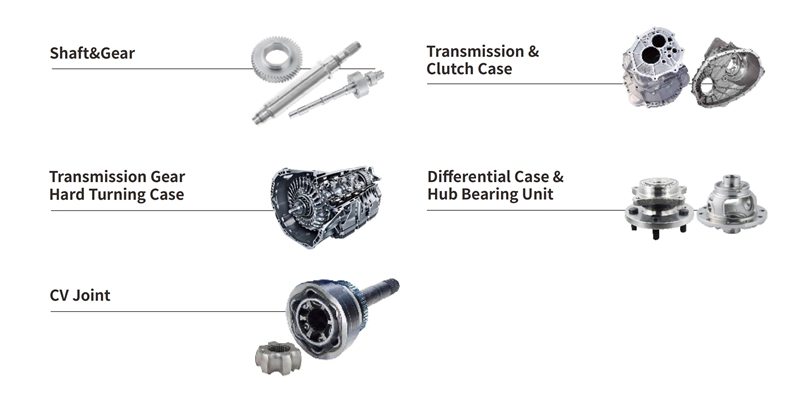

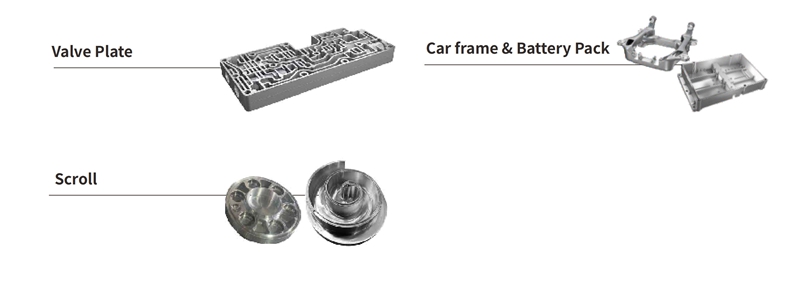

Transmission system

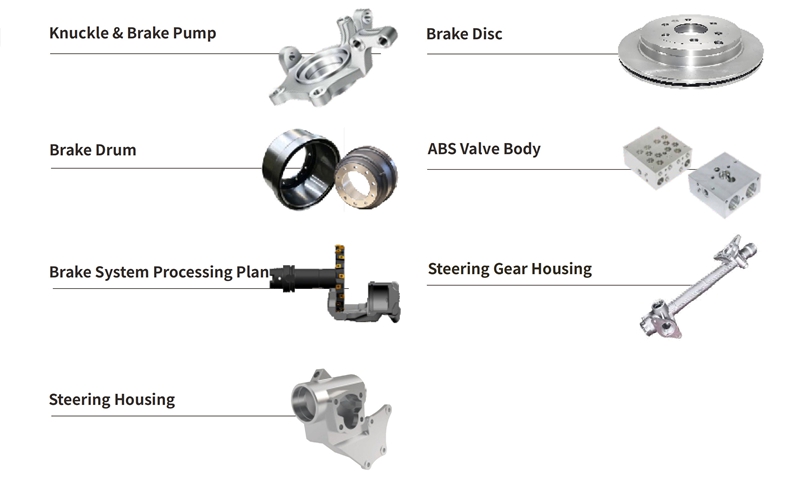

Steering & braking system

Body & auxiliary system

Partner:

If you have any questions, please contact our Executive Manager and we will get back to you as soon as possible

We are looking for business partners to establish dealerships or become authorized distributors. Join our network and embark on a journey of growth and success with Halnn. You can contact us via market@halnn-group.com or click here .

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.