Bearings | Gears | Drive Shafts | Main Shafts |

|  |  |  |

Hubs | Planetary Carriers | Blades | Hydraulic Valves |

|  |  |  |

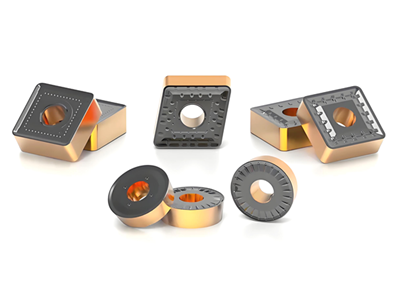

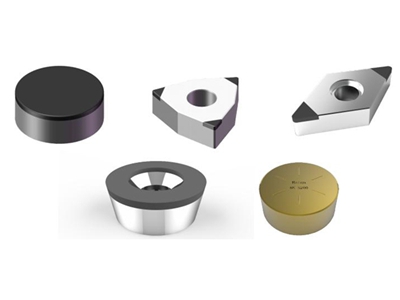

Pre-Heat Turning |  | Carbide inserts are used for rough machining of gear end faces, bearing inner/outer diameters, and shafts, supporting deep cuts and high productivity. |

Post-Heat Hard Turning |  | CBN inserts are ideal for hardened components (HRC60+), offering outstanding wear resistance, dimensional stability, and surface quality. |

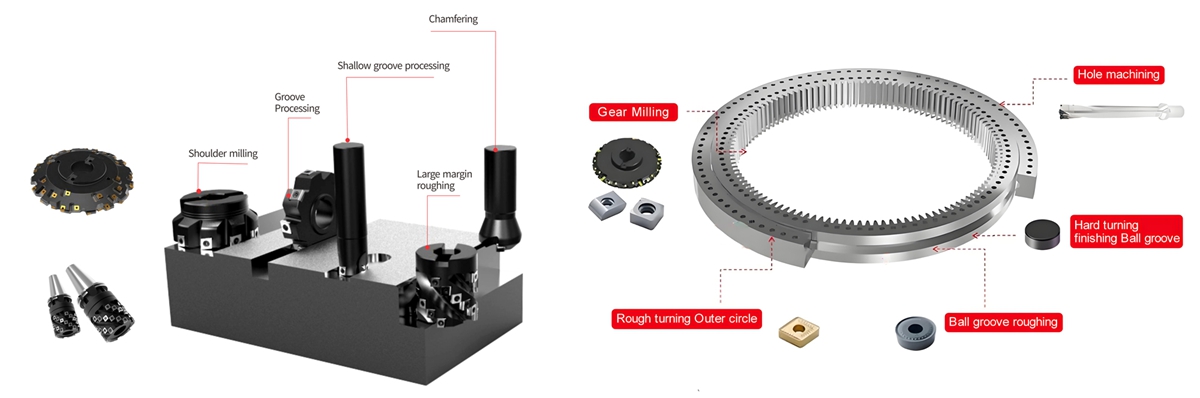

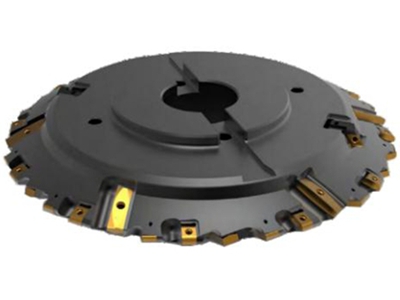

Gear Profile Milling |  | Rough and pre-grind milling cutters for high-accuracy gear profiles. Long tool life and consistent performance. |

High-Speed Gear Hobbing |  | Suitable for modules M5–M38 with optimized tooth arrangements for rough and semi-finishing of external teeth. |

Gear Shaper Cutters |  | Designed for small-module (M3.5–M10) and internal gears. Indexable design, no regrinding required. |

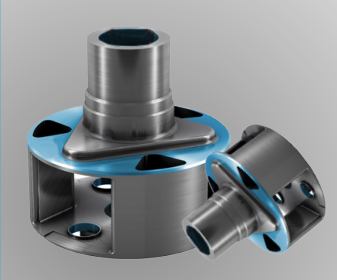

Planet Carrier Milling |  | Anti-vibration three-edge cutters engineered for large overhangs and deep cuts, reducing chatter and improving efficiency. |

Hub Milling |  | Multi-edged double-sided inserts with extremely high material removal rates. |

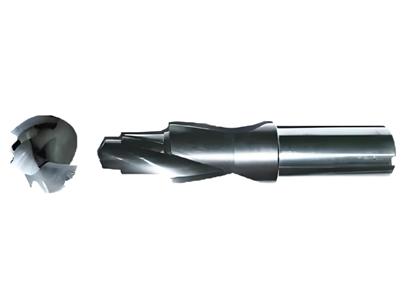

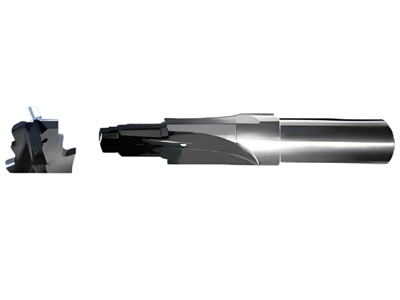

Crown Drill |  | Quick-change design, internal cooling, and excellent chip evacuation for complex deep-hole drilling in hubs and bearings. |

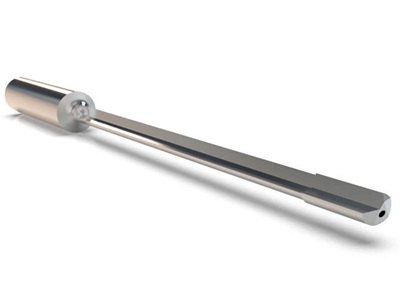

Gun Drills |  | Available in brazed, solid carbide, and indexable designs, suitable for Ra <2 finish. Custom depths supported. |

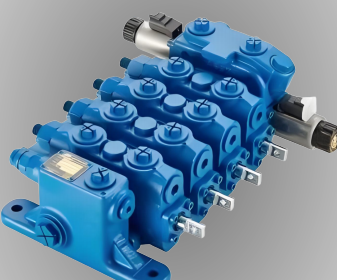

Hydraulic Valve Drilling |  | Composite drills, reamers, and T-slot cutters ensure Ra0.4–Ra0.8 surface finish and high alignment precision. |

Blade Machining |  | PCD inserts minimize burrs and delamination when drilling composite materials. |

Staggered Tooth Thread Mills |  | For large-diameter internal threads (M30–M64), high-speed cutting with internal cooling and lower tooling cost. |

Thread Taps |  | TIN-coated HSS taps for high-hardness materials (HB280–330), offering excellent chip control and guidance. |

Damping Boring Tools |  | Designed for large overhangs with low-vibration performance to ensure excellent surface finishes. |

CMR / CMB Rough and Finish Boring Tools |  | Standard and non-standard solutions for high-precision hole machining in hubs and planetary carriers. |

Composite Forming Reamers |  | Used in hydraulic valve machining, achieving Ra0.4 surface roughness for sealing and assembly accuracy. |

If you have any questions, please contact our Executive Manager and we will get back to you as soon as possible

We are looking for business partners to establish dealerships or become authorized distributors. Join our network and embark on a journey of growth and success with Halnn. You can contact us via market@halnn-group.com or click here .

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.