Description: PCD Inserts

Component Materials: Reinforced plastic, Wood, Aluminum alloy, Copper alloy, Tungsten Carbide, Graphite, Metal matrix composites, Composite, Carbon Finber, Carbide / Cemented Carbide Roller

Whether customized: can be customized

Whatsapp: +8613271562251

Email: halnn@halnn-group.com

1. PCD Grade and Application

| Grade | Granularity (μm) | Characteristics | Application | Microstructure |

| CDW850 | Submicron | Ultra-fine grain structure, strong edge sharpness and edge durability | High precision machining, mirror surface machining, suite for aluminum alloy that required high on the chipping performance, mainly used for machining Ti alloy and other composites |  |

| CDW002 | 2μm | High cobalt content, Good electrical machine performance, excellent toughness, Good roughness machining, more convinent for complec tool processing | Mainly used for engrave milling cutter and thread cutting tool, and also cutting tools for wear-resistant parts, used in woodworking saws, particleboard and the tools for machining silicon aluminum alloy |  |

| CDW005 | 5μm | Excellent electric spark and machinability, good toughness, wear resistance and edge quality | It suits for good surface quality processing, mainly used for machining PMMA, Silicion alloy and metal cell phone shell outlin and used in the wood cutting tools, saws industry |  |

| CDW010 | 10μm | Universal PCD Grade, good toughness and high abrasive resisitance | Suit for single tool for rough machining, especially for wood molding, medium and low silicon aluminum alloy parts (such as piston). |  |

| CDW025 | 25μm | High wear resistance and edge quality | Suit for high Silicion Aluminum alloy, MMC, Tungsten carbide and ceramic, graphite,wear resistant parts, mainly used in wood Wood finishing insert and saws |  |

| CDW302 | 2~30μm | Mixed 2μm and 25μm,good wear resistance and edge quality and edges strength | It mainly used for machining MMC, high Silicion Aluminum calloy, high strength cast iron and other application. |  |

2.Halnn recommend cutting condition

| Component Materials | Recommend PCD Grade | Vc(m/min) | Fr(mm/r) | ap(mm) | |||

| Aluminum alloy 4-8%Si | CDW010 | CDW302 | CDW005 | CDW850 | 100-5000 | 0.03-0.5 | 0.1-3.0 |

| Aluminum alloy 9-13%Si | CDW010 | CDW302 | CDW850 | 100-3000 | 0.03-0.5 | 0.1-3.0 | |

| Aluminum alloy >13%Si | CDW010 | CDW302 | CDW025 | CDW850 | 100-2500 | 0.03-0.4 | 0.1-2.5 |

| Copper alloy | CDW010 | CDW302 | CDW025 | CDW850 | 100-1000 | 0.03-0.3 | 0.1-3.0 |

| Titanium alloy | CDW850 | CDW005 | 100-200 | 0.05-0.2 | 0.1-2.0 | ||

| Tungsten Carbide Co < 16% | CDW302 | CDW025 | CDW010 | 15-40 | 0.1-0.25 | 0.1-1.0 | |

| Tungsten Carbide Co > 16% | CDW302 | CDW025 | CDW010 | 10-30 | 0.03-0.1 | 0.05-0.3 | |

| Wood | CDW010 | CDW302 | CDW005 | CDW002 | 100-4000 | 0.1-0.4 | 0.1-3.0 |

| Graphite | CDW302 | CDW025 | CDW010 | 100-600 | 0.1-0.5 | 0.05-2.0 | |

Metal matrix Composites | CDW302 | CDW025 | CDW010 | 300-600 | 0.1-0.4 | 0.2-1.5 | |

Composites(Carbon Fiber) | CDW302 | CDW025 | CDW010 | 200-2000 | 0.05-0.3 | 0.1-3.0 | |

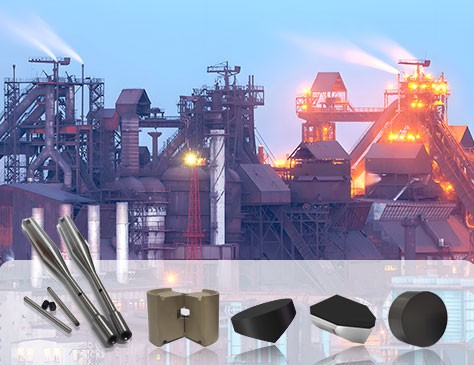

Application Industry

Standing stock of standard PCD Inserts;PCD Inserts Specifications Accept customization:

| Special PCD Inserts | |||

|

|

|

|

RCMX | PCD Notching tools | PCD Notching tools | PCD Notching tools |

|

| |

|

CCGW | TPGN-HS | TCGW | TPGN |

|

|

|

|

PCD Chipbreaker inserts | PCD Chipbreaker inserts | PCD Chipbreaker inserts | PCD Chipbreaker inserts |

Mode: Type: Application:Hydraulic industry

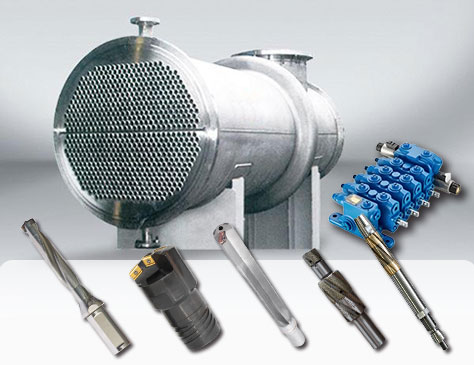

Mode:Milling,Drilling,Reaming Type:PCD Tools,Carbide Tools Application:Aerospace Field

Mode:RNMN RCMX-V RCMX-Y PCD Type:BN-K1,BN-S20,CDW010 Application:Heavy Machining

Mode:Drilling, Boring, Reaming Type:Gun Drills, Solid Carbide Drill Application:Hole Machining

We are looking for business partners to establish dealerships or become authorized distributors. Join our network and embark on a journey of growth and success with Halnn. You can contact us via market@halnn-group.com or click here .

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.