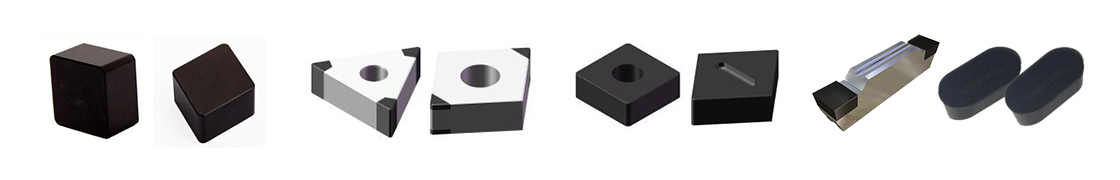

1. Halnn CBN Materials for machining Gray Cast Iron

Insert Grade | Suited Materials | Machining Type | Typical Application |

BN-S300 | Gray Cast Iron | Roughing, Finishing | Brake Disc, Cast Iron Engine,Gearbox, Cylinder Liner |

BN-S30 | Gray Cast Iron | Roughing | Brake Disc, Cast Iron Engine,Gearbox, Cylinder Liner |

BN-K20 | Gray Cast Iron | Semi-Finishing, Finishing | Brake Disc, Cast Iron Engine,Gearbox |

BNK30 | Gray cast iron, Iron based alloy | Semi-Finishing,Finishing | Brake Disc, Brake Drum, Cast Iron Engine, Gearbox |

2. The cutting condition of Halnn CBN Insert

CBN Content | Characteristics | Halnn CBN | Cutting Depth | Condition |

High Content | Toughnes(Roughing)

| BN-S30 | 1-10mm | Semi-Interrupt |

BN-S300 | ≤2mm | Continuous | ||

BNK30 | ≤1.5mm | Continuous | ||

BN-K20 | ≤0.5mm | Continuous |

3. The advantages of Halnn CBN Inserts machining gray cast iron part

(1) Improve Efficiency: Compared with coating carbide insert, it can realize high speed machining,and the suitable linear speed will be: 250~450m/min for roughing process, 450~800m/min for finishing process. And it also be suitable for the high speed milling with 1500m/min or above. The efficiency will be about 2 times more than cabide insert.

(2) Improve Tools Durability: The tool life of Halnn CBN Insert is about 15 times of carbide insert.

(3) Improve Roughness: Halnn BN-K20 and BN-S30 can receive the roughness within Ra1.6, is much better than carbide insert.

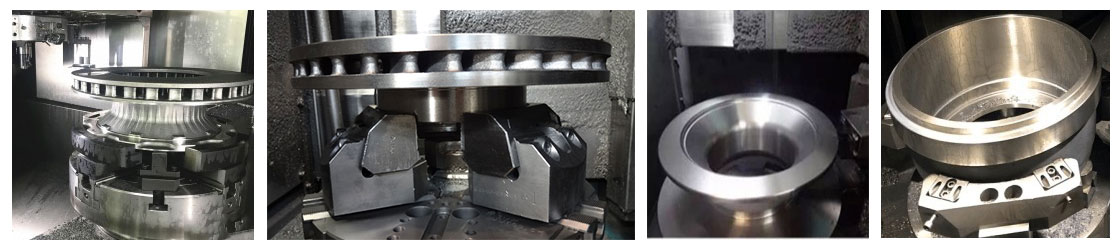

(4) Characteristics of Halnn CBN inserts: BN-S30 and BN-S300 adopt non-metal adhesive, improved the thermal conductivity and the strength, not only extand the insert lifetime, but also improve the impact resistance. And BN-S30 can be used for roughing process, BN-S300 can be used for finishing process. BN-K20 and BNK30 belong to brazed pcbn insert, both of them can be used for finishing process. the tools of processing brake disc, brake drum as follows:

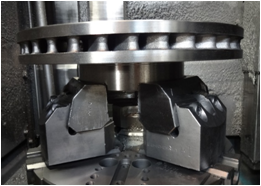

Application Case 1

| Item | Brake Disc Manufacturer | Advantages compraison |

Component Materials | GG25(HT250) |

With BN-S300 Solid cbn insert, The tool life improved 45% |

Machining Condition | Roughing,dry cutting | |

Selected Insert | BN-S300 CNGN120716 | |

| Cutting Parameters | Vc=950m/min,Fr=0.7mm/r,ap=2mm |

Application Case 2

| Item | Brake Disc Manufacturer | Image |

| Component Materials | GC250 (HT250) |  |

| Machining Process | Finishing, Dry Cutting | |

| Hardness | HB180~HB220 | |

| Selected insert | CNGN120412 | |

| Testing Performance Comparison | ||

Insert Materials | Cutting Parameters | Machining Qty |

Halnn BNK30 | Vc=1150,Fr=0.2,ap=0.25 | 640 |

Other PCBN | Vc=880,Fr=0.2,ap=0.25 | 475 |

The tool life improved 35%, and the efficiency improved about 30% ! | ||

Application Case 3

| Item | Brake Disc Manufacturer | Image |

| Component Materials | GC250 (HT250) |  |

| Machining Process | Finishing, Dry Cutting | |

| Hardness | HB210 | |

| Selected insert | BN-S300 C06 SCGN090412 | |

| Testing Performance Comparison | ||

Insert Materials | Cutting Parameters | Product Image |

Halnn BN-S300 C06 | Vc=900,Fr=0.25,ap=0.3 |  |

The Tool Life of Coating CBN Inserts improved about 30%, And the roughness Keeped Ra1.6 | ||

Application Case 4

| Item | Brake Disc Manufacturer | Image |

| Component Materials | FC250 (HT250) |  |

| Machining Process | Finishing, Dry Cutting | |

| Hardness | HB170~HB210 | |

| Selected insert | BNK30 TNGA160408-6S | |

| Testing Performance Comparison | ||

Insert Materials | Cutting Parameters | Machining Qty |

Halnn BNK30 | Vc=1000,Fr=0.2,ap=0.3 | 160 |

Other PCBN | Vc=800,Fr=0.2,ap=0.3 | 100 |

The tool life improved 60% ! | ||

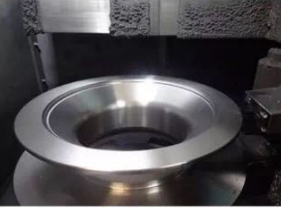

Application Case 5

| Item | Brake Drum Manufacturer | Image |

| Component Materials | GC250 (HT250) |  |

| Machining Process | Finishing, Dry Cutting | |

| Hardness | HB170~HB210 | |

| Selected insert | CNGN120412 | |

| Testing Performance Comparison | ||

Insert Materials | Cutting Parameters | Machining Qty |

Halnn BN-S300 | Vc=1150,Fr=0.2,ap=0.25 | 640 |

Other PCBN | Vc=880,Fr=0.2,ap=0.25 | 471 |

The tool life improved 35%, and the Efficiency improved about 30%! | ||

Partner:

If you have any questions, please contact our Executive Manager and we will get back to you as soon as possible

We are looking for business partners to establish dealerships or become authorized distributors. Join our network and embark on a journey of growth and success with Halnn. You can contact us via market@halnn-group.com or click here .

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.