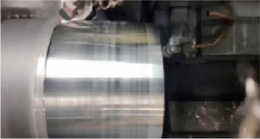

Ceramic Inserts for Superalloy

Description: Special Ceramic inserts machining Superalloy materials

Processing Materials: Superalloy

Processing Types: Roughing, Semi-Finishing, Finishing

Whatsapp: +8613271562251

Email: halnn@halnn-group.com

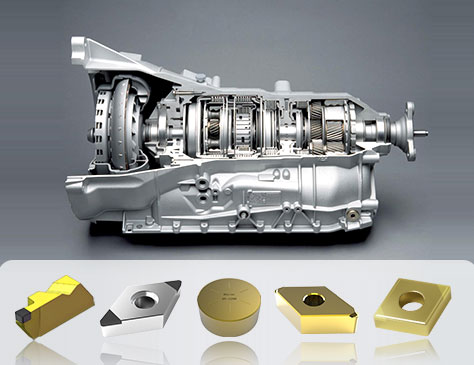

1.Insert Gredes

| Grade | Main Ingredient | Application |

| SH100,SH200 | AlOSiN | Use to Milling and Rough Turning Superalloy |

| S100,S200 | Al₂O₃ and SiCw | Use to finish turning Superalloy |

Product advantages

(1) Good wear resistance during high-speed cutting make stable cutting;

(2) Advanced materials with excellent edge strength;

(3) Excellent thermal shock resistance and thermal conductivity;

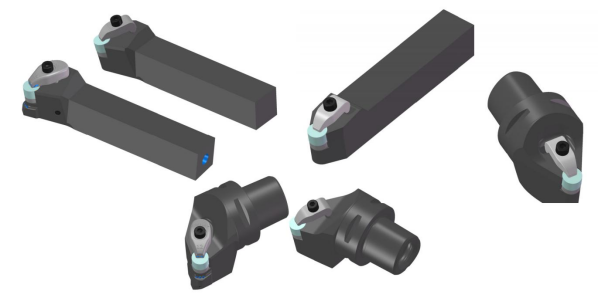

2.Special Turning Holder for Superalloy

1.SH100 turning Superalloy 718 material

| Material: Superalloy |

| Grade: SH100 | |

| Cutting parameters: Vc=300m/min, Fr=0.1mm/rev, ap=1.5mm | |

| Cutting status: dry cutting |

| Inserts material | Half depth of cut wear on tool flank | Groove wear on tool flank | Tool wear morphology |

| Halnn SH100 | 215μm | 290μm |  |

| Other brand | 230μm | 260μm |  |

2.S100 Turning Superalloy case

| Material: Superalloy |

| Grade: S100 | |

| Cutting parameters: Vc=300m/min, Fr=0.1mm/rev, ap=0.5mm | |

| Cutting status: dry cutting |

| Inserts material | Half depth of cut wear on tool flank | Groove wear on tool flank | Tool wear morphology |

| Halnn S100 | 100μm | 650μm |  |

| Other brand | 100μm | 810μm |  |

Mode:CBN tools Type:Solid CBN Insert,PCBN Insert Application:Hardened Steel

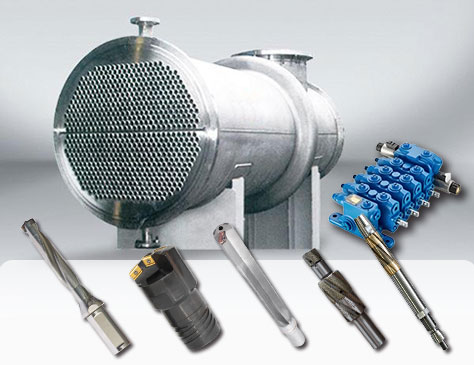

Mode:Milling,Drilling,Reaming Type:PCD Tools,Carbide Tools Application:Aerospace Field

Mode:Turning, Milling, Hole-making Type:PCBN Insert, PCD Tools Application:Auto Parts

Mode:Drilling, Boring, Reaming Type:Gun Drills, Solid Carbide Drill Application:Hole Machining

We are looking for business partners to establish dealerships or become authorized distributors. Join our network and embark on a journey of growth and success with Halnn. You can contact us via market@halnn-group.com or click here .

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.