Halnn's Heavy-Duty PCBN Inserts represent a breakthrough in machining technology, designed to meet the rigorous demands of heavy-duty cutting. Engineered for exceptional performance, these inserts deliver superior wear resistance, hardness, and thermal stability, making them the ideal choice for machining hard materials under challenging conditions.

| Heavy-duty CBN Inserts |

|

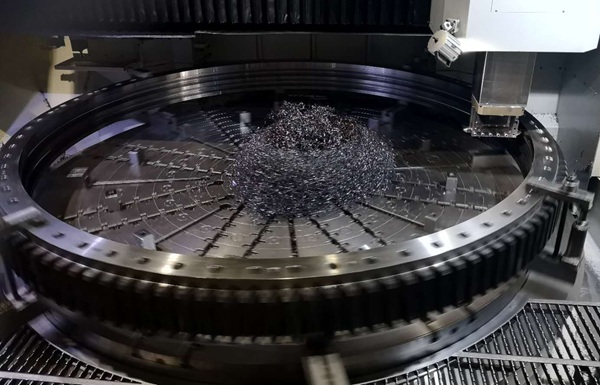

Wind Turbine Bearing Case

·Material: 42CrMo4, Hardness: HRC58-63

·Insert Model: BN-H200 RNGN120300

·Cutting Parameters: ap=1-1.5mm (rough), ap=0.15mm (finish), Fr=0.35mm/r, Vc=230m/min, dry cutting

·Result: Processed four pieces per shift (diameter 3000mm+), achieving record-breaking efficiency.

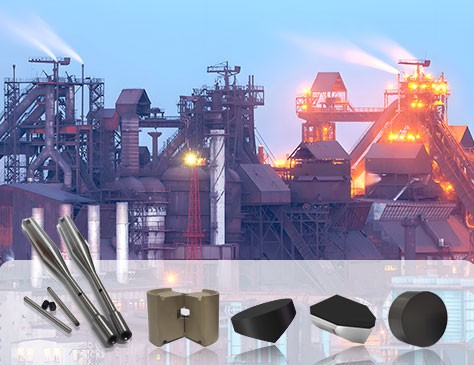

Roll Machining Case

·Material: Cast high-speed steel, Hardness: HRC65-68

·Insert Model: BN-H200 RCGX120700

·Cutting Parameters: Vc=40m/min, ap=0.5mm, Fr=0.8mm/r

·Result: 50% higher efficiency and 4x durability compared to a leading ceramic tool brand.

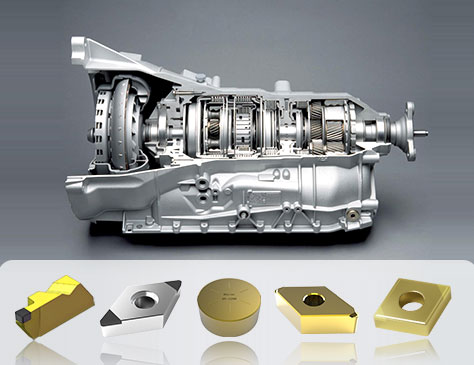

Mode:CBN tools Type:Solid CBN Insert,PCBN Insert Application:Hardened Steel

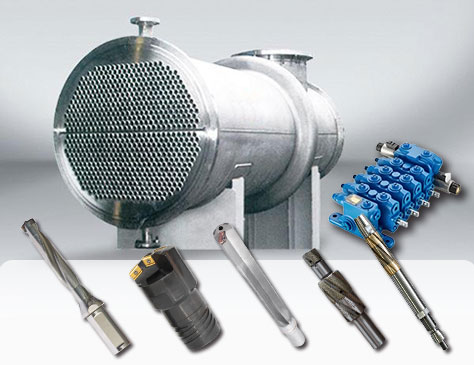

Mode:Turning, Milling, Drilling, Boring Type:Crown Drill, PCD Inserts Application:Wind Energy

Mode:RNMN RCMX-V RCMX-Y PCD Type:BN-K1,BN-S20,CDW010 Application:Heavy Machining

Mode:Drilling, Boring, Reaming Type:Gun Drills, Solid Carbide Drill Application:Hole Machining

We are looking for business partners to establish dealerships or become authorized distributors. Join our network and embark on a journey of growth and success with Halnn. You can contact us via market@halnn-group.com or click here .

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.