·HP154U – High-hardness substrate with thick TiCN and Al₂O₃ coatings for excellent wear resistance, ideal for continuous heavy turning.

·HP254U – Balanced hardness and strength substrate with thick TiCN and Al₂O₃ coatings, offering outstanding wear resistance. Suitable for both continuous and light intermittent machining, providing excellent versatility.

·HP354U – High-strength substrate with thick TiCN and Al₂O₃ coatings, delivering exceptional impact resistance, ideal for heavy interrupted turning.

Different Solutions for Different Machining Conditions

| HLR – Light Cutting |

| Wide chip-breaking range with smooth cutting performance, ideal for continuous cutting or heavy turning with small machining allowance. | |

| HIR – Interrupted Cutting |

| Reinforced cutting edge for high safety and reliability, suitable for unstable conditions such as interrupted heavy turning. | |

| HLR – Light Cutting |

| Double-sided low-parameter groove design for stable conditions or small allowance machining, ensuring excellent chip flow control. | |

| HGR – General Cutting |

| Balanced groove design for both chip control and strength, suitable for continuous and light interrupted heavy turning. | |

| HGR – General Cutting |

| Double-sided universal groove structure, ensuring chip control and strength, offering high cost-effectiveness under stable conditions. |

Recommended Cutting Speed (Vc: m/min)

| Continuous ·Interrupted Cutting | ·Strong Interrupted Cutting | |

| HP152C | HP252C | KM402C |

| 160(100-220) | 140(80-200) | 120(70-150) |

Recommended Depth of Cut & Feed Rate (Ap: mm Fn: mm/r)

| Continuous Cutting | Light Interrupted Cutting | Interrupted Cutting | Strong Interrupted Cutting | |

| HLR (Single-Sided) | Ap: 2~8 Fn: 0.3~1.0 | Ap: 2~8 Fn: 0.3~0.6 | ---- | ---- |

| HGR (Single-Sided) | ---- | Ap: 4~15 Fn: 0.5~1.3 | Ap: 4~10 Fn: 0.5~0.9 | ---- |

| HIR (Single-Sided) | ---- | ---- | Ap: 5~20 Fn: 0.7~1.5 | Ap: 5~15 Fn: 0.7~1.0 |

| HLR (Double-Sided) | Ap: 2~8 Fn: 0.3~1.0 | Ap: 2~8 Fn: 0.3~0.6 | ---- | ---- |

| HGR (Double-Sided) | Ap: 4~12 Fn: 0.5~1.0 | Ap: 4~8 Fn: 0.5~1.0 | ---- | ---- |

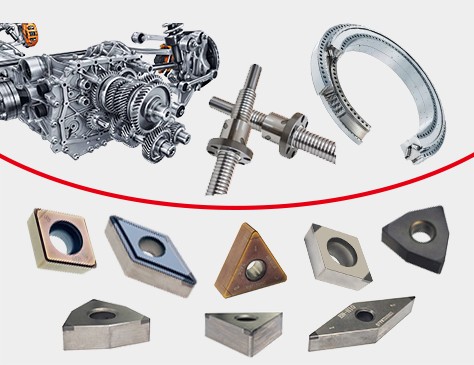

Workpiece: Wind Power Main Shaft

·Workpiece Material: Alloy Steel

·Lathe Type: Horizontal Lathe

·Insert: HP15U SNMM250924-HGR

·Comparison Insert: Well-known Manufacturer

·Processing Content: Outer Diameter Rough Turning

·Insert Change Criteria: Surface Finish, Excessive Insert Wear

·Cooling Type: Dry Cutting

·Cutting Parameters: Vc = 80-120 m/min, Fn = 0.9 mm/rev, Ap = 5-10 mm

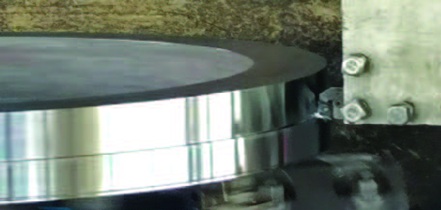

Workpiece: Slewing Bearing

·Workpiece Material: 40CrNiMo

·Lathe Type: CNC Lathe

·Insert: HP154U CNMG190616-HGR

·Comparison Insert: Well-known Manufacturer

·Processing Content: Outer Diameter Turning

·Insert Change Criteria: Surface Finish or Severe Insert Wear

·Cooling Type: Dry Cutting

·Cutting Parameters: Vc = 80-120 m/min, Fn = 0.63 mm/rev, Ap = 2-8 mm

Workpiece: Oil Pipe Joint

·Workpiece Material: 40CrNiMo

·Lathe Type: CNC Lathe

·Insert: HM452U CNMM250924-HIR

·Comparison Insert: Well-known Manufacturer

·Processing Content: Outer Diameter & Face Turning

·Insert Change Criteria: Surface Finish or Severe Insert Wear

·Cooling Type: Dry Cutting

·Cutting Parameters: Vc = 80-120 m/min, Fn = 1.3 mm/rev, Ap = 8-15 mm

Mode:RNMN RCMX-V RCMX-Y PCD Type:BN-K1,BN-S20,CDW010 Application:Heavy Machining

Mode:Solid CBN Insert Type:BN-K1,BN-S20 Application:Wear Parts

Mode:Drilling, Boring, Reaming Type:Gun Drills, Solid Carbide Drill Application:Hole Machining

Mode:CBN tools Type:Solid CBN Insert,PCBN Insert Application:Hardened Steel

We are looking for business partners to establish dealerships or become authorized distributors. Join our network and embark on a journey of growth and success with Halnn. You can contact us via market@halnn-group.com or click here .

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.

For all inquiries fill in the form below to send us a brief message,and we will get back to you as soon as possible.