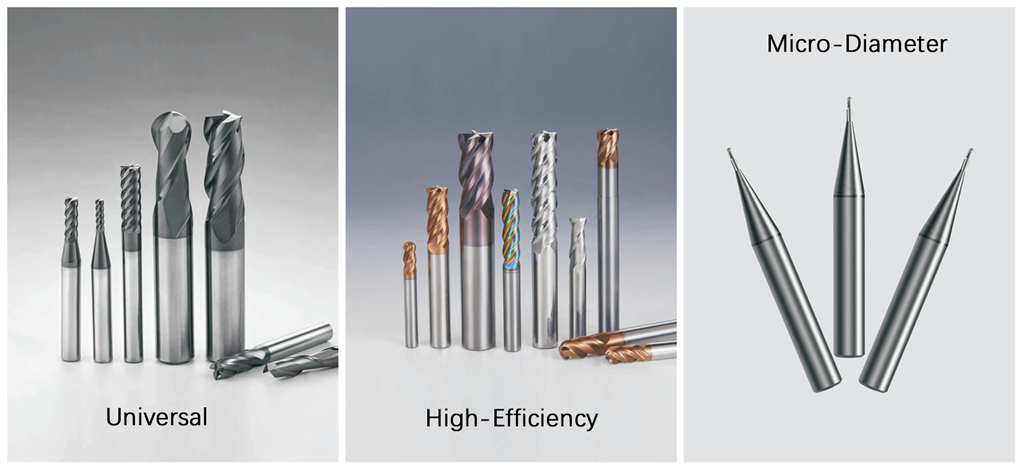

With advanced coating technologies and optimized geometries, Halnn end mills offer extended tool life and superior surface finish — especially suitable for high-speed milling, hard material machining, and precision parts processing.

Mode:Milling,Drilling,Reaming Type:PCD Tools,Carbide Tools Application:Aerospace Field

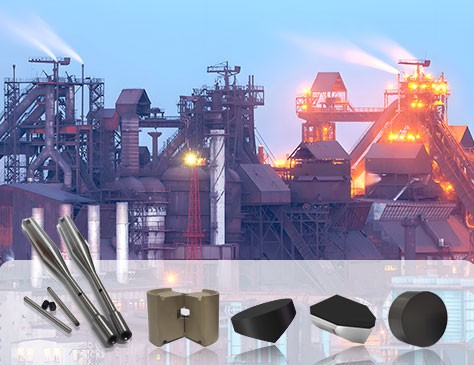

Mode:CBN tools Type:Solid CBN Insert,PCBN Insert Application:Hardened Steel

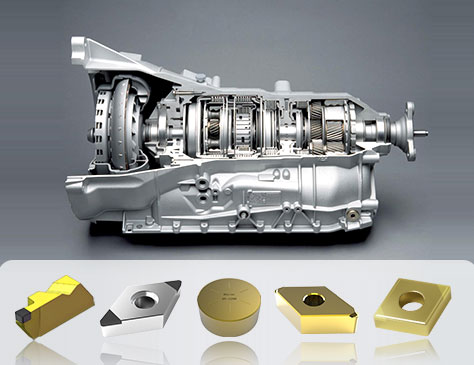

Mode:RNMN RCMX-V RCMX-Y PCD Type:BN-K1,BN-S20,CDW010 Application:Heavy Machining

Mode: Type: Application:Hydraulic industry

We are looking for business partners to establish dealerships or become authorized distributors. Join our network and embark on a journey of growth and success with Halnn. You can contact us via market@halnn-group.com or click here .

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.