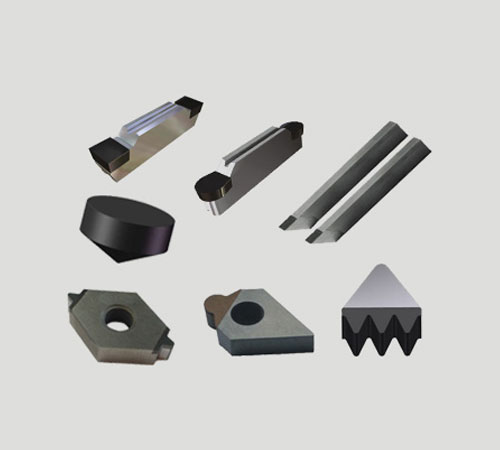

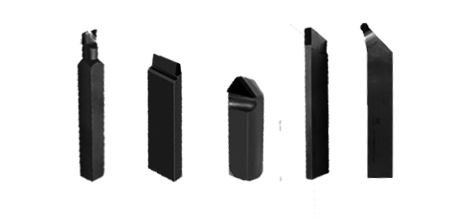

Piston groove tools are specialized machining instruments designed to create precise grooves in piston components. These grooves are crucial for housing piston rings, which are essential for maintaining the seal and proper functioning of internal combustion engines. >>

In the ever-evolving landscape of industrial machining, precision and durability are paramount. One of the standout innovations in this realm is the use of Piston PCD inserts. These cutting tools are essential for manufacturers aiming to enhance their machining processes, particularly in the automotive and aerospace industries. This article delves into the benefits and applications of Piston PCD inserts and Piston PCD tools, emphasizing their role in optimizing performance and cost-effectiveness. >>

PCD wheel hub insert is specially used for the external facing processing of aluminium alloy wheel hubs for cars. It is a high performance cutting tool and plays an important roles in automotive manufacturing industry and related fields. >>

High-speed steel, as a tool steel material with high hardness, high wear resistance and high compressive strength, occupies a pivotal position in the field of metal processing. It is widely used in manufacturing various cutting tools, molds and other high-strength tools. This article will deeply explore the features of Halnn CBN inserts for processing high-speed steel, and demonstrate its application effects in different scenarios through specific cases. >>

PCD (Polycrystalline Diamond) milling tools are a type of high-performance cutting tool used in various machining applications. They are designed for high-speed and high-precision milling operations, particularly in industries where materials are difficult to machine or require exceptionally fine finishes. Below is a detailed description of PCD milling tools, including their characteristics, uses, manufacturing processes, advantages, and best practices. >>

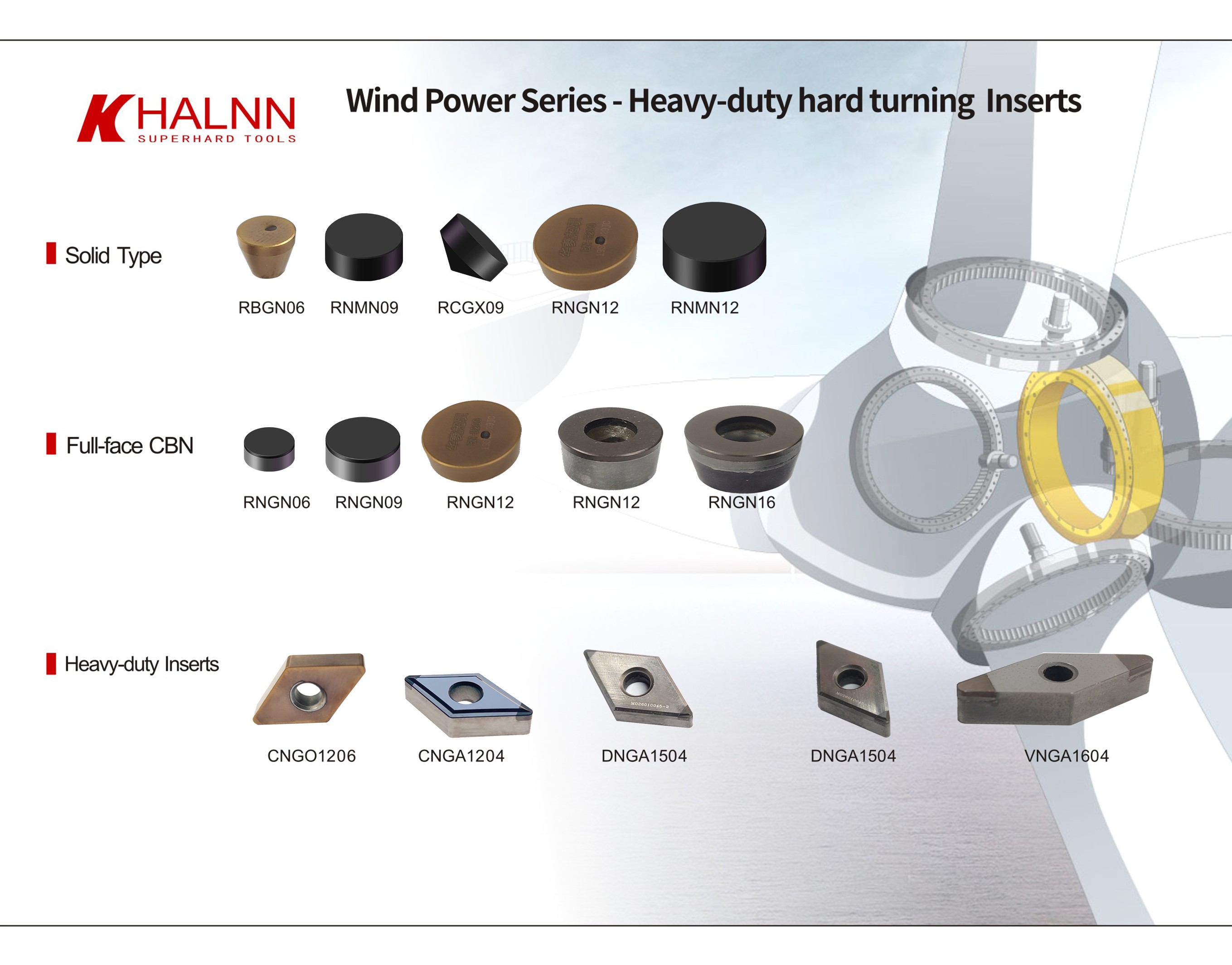

For wind turbine blade flange hole drilling, Halnn offers PCD fully laminated U drill inserts with excellent wear resistance, mainly W-shaped and S-shaped, which can be indexed 3-4 times to reduce production costs, and at the same time, it can withstand higher cutting speeds and feed speeds, combined with excellent rigidity of the tool holder, to achieve stable and efficient drilling while maintaining dimensional accuracy. >>

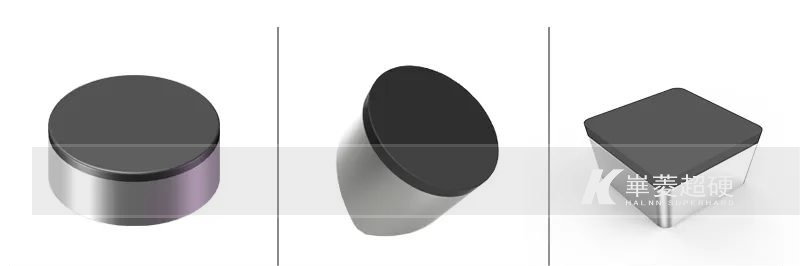

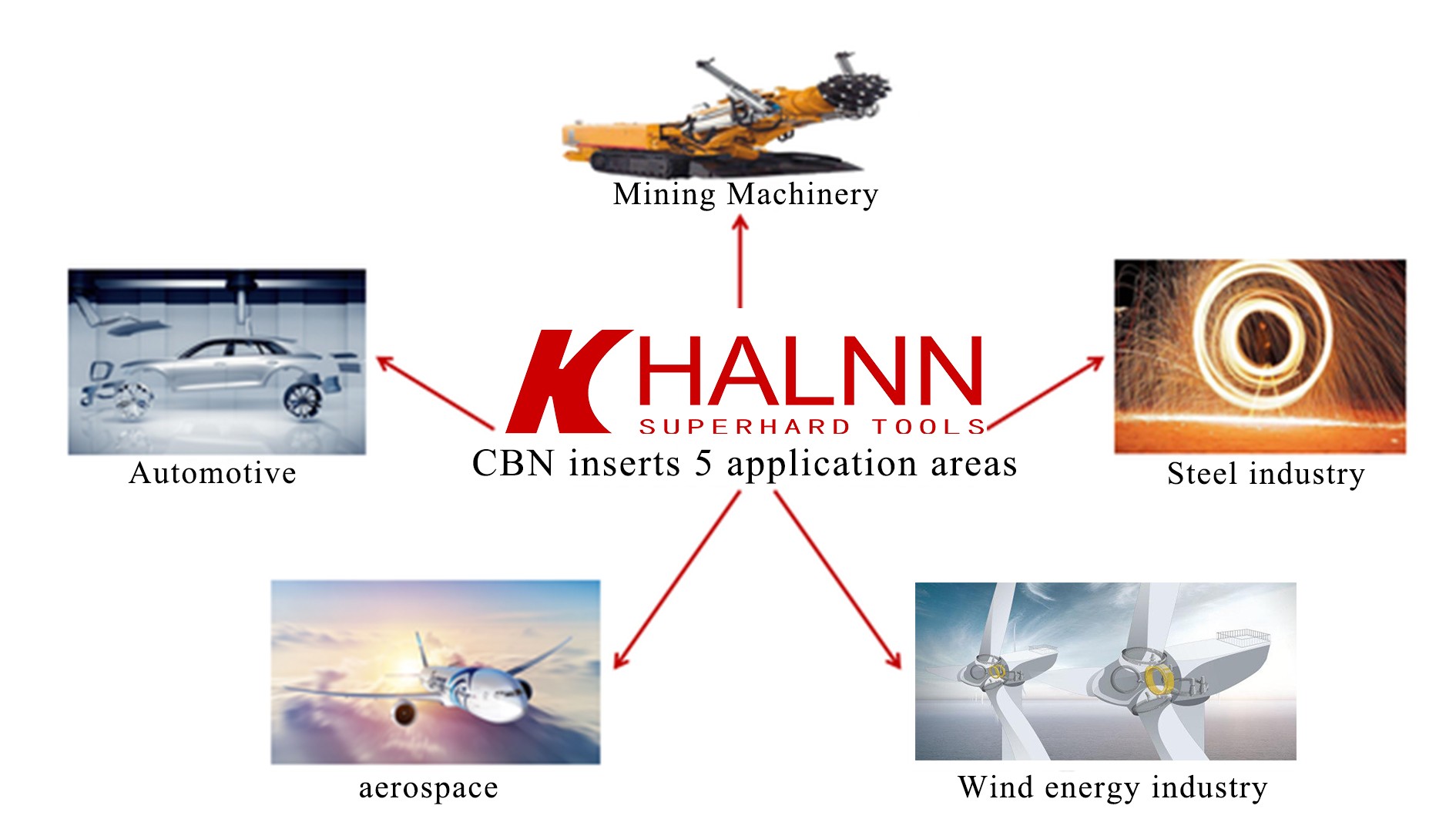

Due to the high hardness and good wear resistance, Halnn`s CBN inserts in heavy dutyTM series have become an ideal selection for supporting suppliers in fields such as rolling mills, wind power bearings, mining machinery, and heavy machinery. >>

CBN tools, i.e. cubic boron nitride tools, are known as the "teeth of industry" because of their wide application in various machining. For brake discs (cast iron), gears (hardened steel), rolls (high-speed steel) and other common situations in the cutting process, in the face of high cutting forces, high cutting temperatures, machining hardening tendency, tool wear serious problems, you can consider the following different types of CBN tools to deal with >>

What kind PCBN inserts of insert is good for turning hardened steel? The specific choice of what PCBN inserts, but also need to judge according to the actual processing conditions. The following Halnn from the machining allowance, processing conditions of these two aspects to introduce. >>

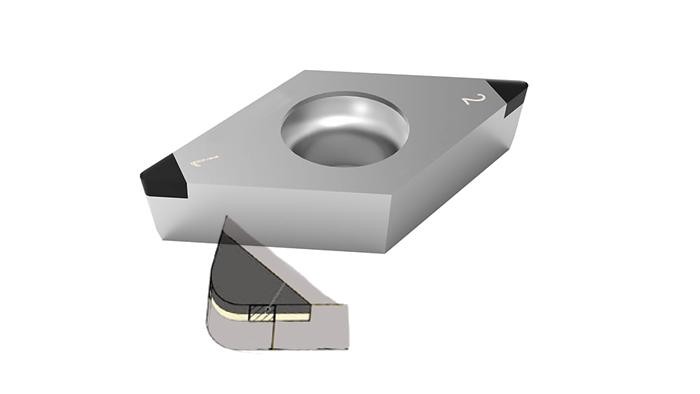

This article explores the significance of Cubic Boron Nitride (CBN), a superhard material second only to diamond in hardness.The article details common structures of CBN inserts, applications in various workpiece materials, and provides insights into processing techniques and wear patterns. Selection criteria for CBN inserts, including holders and models, are discussed, along with recommended cutting parameters. The piece concludes with common forms of CBN insert wear, emphasizing the importance of suitable replacements for optimal performance in machining. >>

Halnn's innovations in the field of CBN insert technology, especially the in-depth research and development achieved in CBN inserts with wiper. PCBN inserts with wiper have higher surface quality and higher machining efficiency compared to traditional PCBN inserts, making them ideal for handling high-precision and high-surface-demanding machining tasks. Halnn has successfully replaced traditional CBN tools with BN-S300 SCGN090412 CBN inserts with wiper, and has achieved significant performance improvements. >>

We are looking for business partners to establish dealerships or become authorized distributors. Join our network and embark on a journey of growth and success with Halnn. You can contact us via market@halnn-group.com or click here .

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.