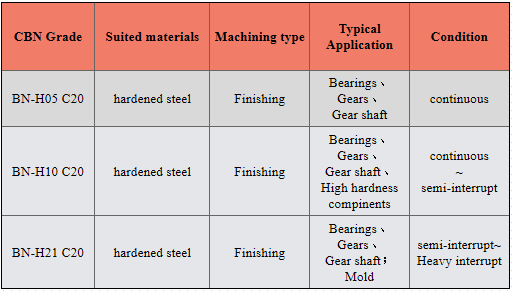

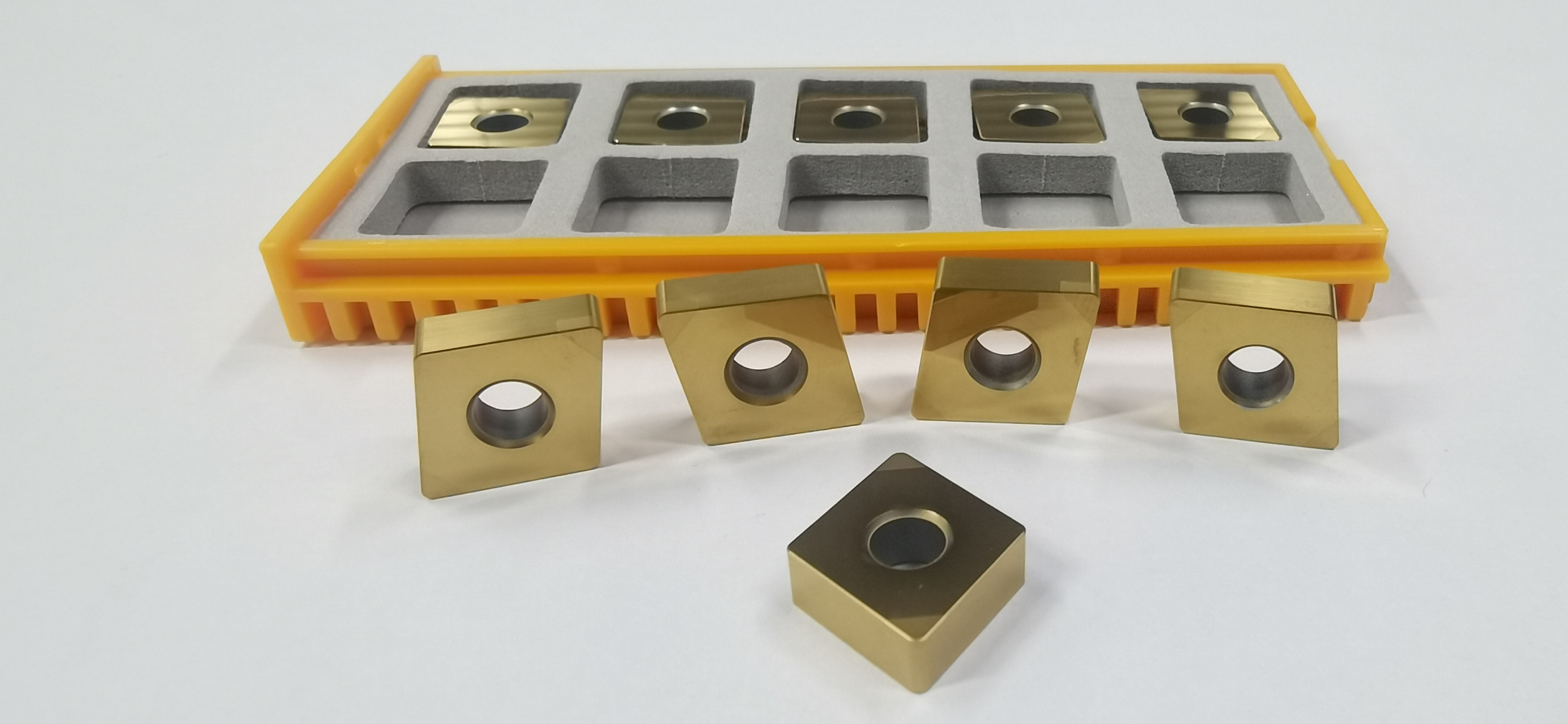

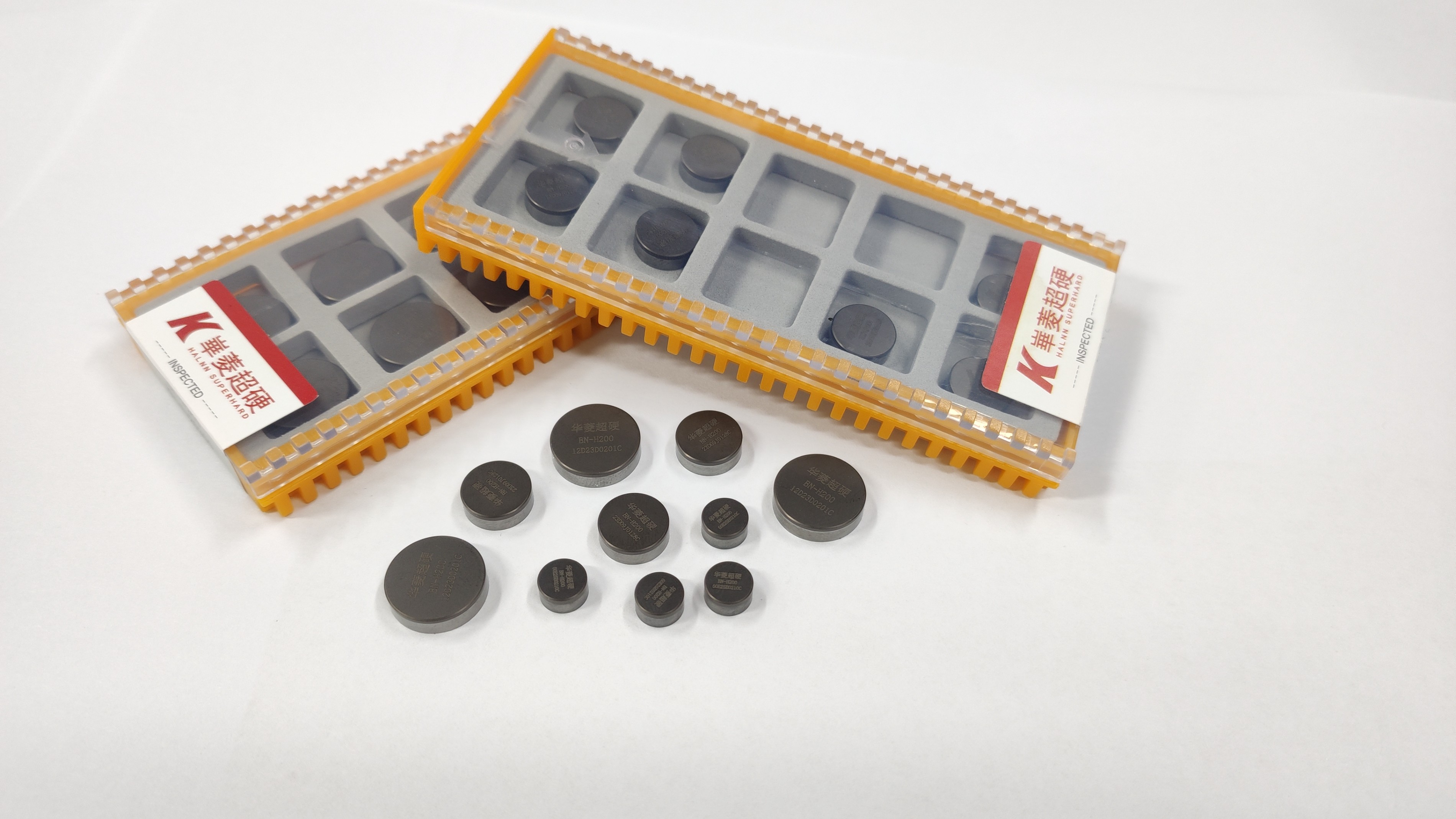

Coated CBN inserts play a key role in gear machining. In order to meet the ever improving and diversifying demands, halnn continues to innovate and diversify its product line. halnn BN-H05 C20 coating CBN inserts are ultra-precision machining grades for continuous cutting with very high surface roughness. interrupt cutting gear Selects Halnn Coating CBN Inserts, In this cases you can see our coated CBN inserts can improve 1.5 times work life and just for normal wear. >>

Halnn offers five coatings to choose from, with different colors representing different properties and conditions. Halnn coating CBN inserts provide excellent cutting stability and life enhancement in the finishing of hardened steels. >>

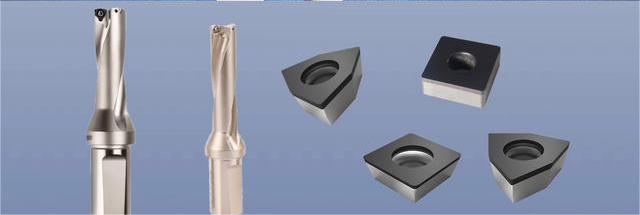

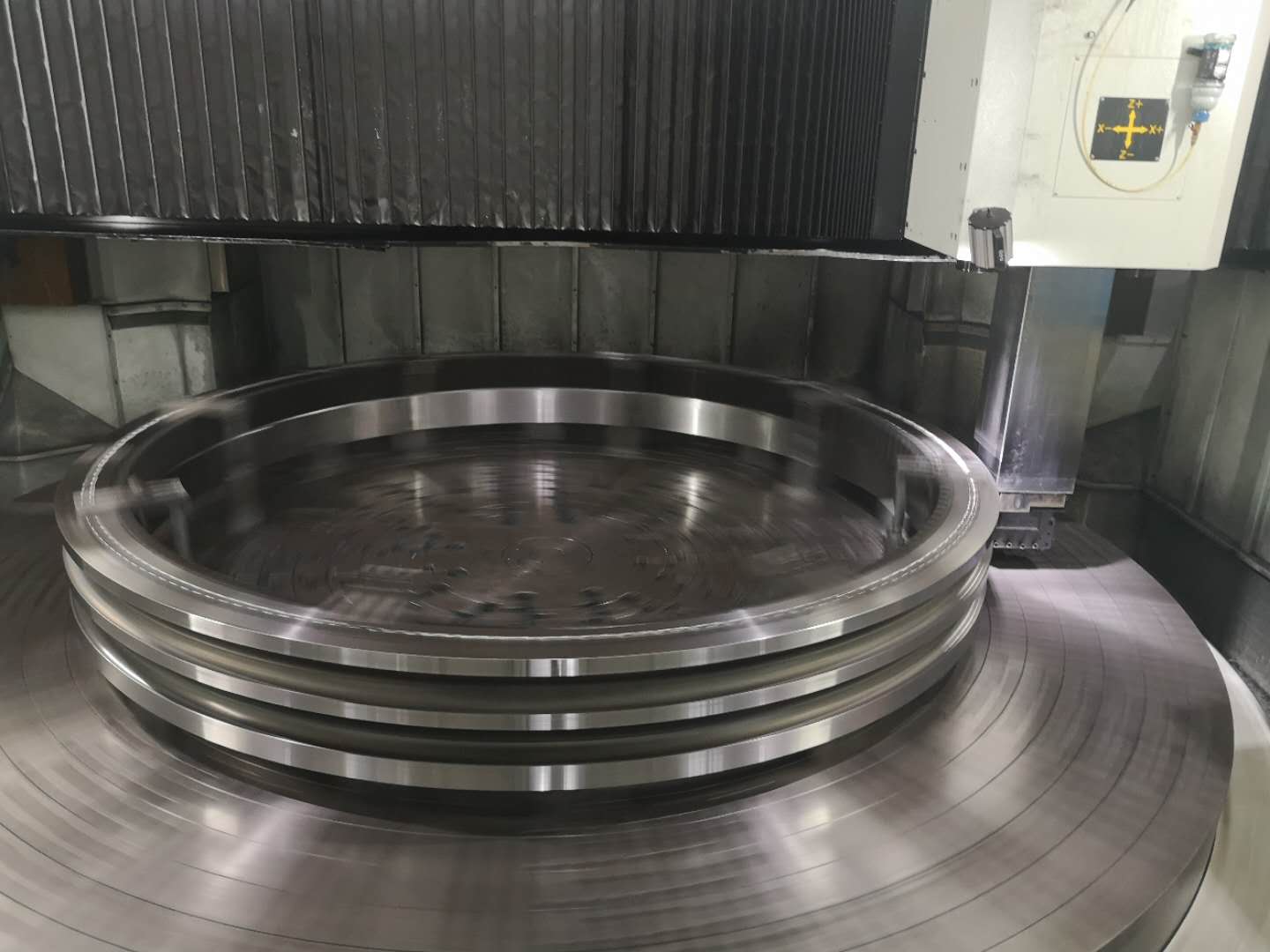

Halnn provides hard turning wind turbine bearing complete tooling solutions.Whether it is wind tuerbine gear machining(mill), rough turning on wind tuerbine bearing outer ring, wind tuerbine bearing machining(raceway) or drilling, we could provide professional solutions to make wind turbine bearing machining more stable and efficient. >>

Halnn crown drill machining wind turbine bearings not only has excellent machining performance, but also cost-efficiency due to the design of removable inserts. >>

PCD (polycrystalline diamond) tools are usually used in the manufacture, grinding and drilling of wind power blades. It gets great advantages in drilling on wind power blade because of its extremely hardness and wear resistance. >>

In wind turbine gear machining, the use of composite PCBN inserts from Halnn improved cutting speed and machining efficiency, and the PCBN inserts for fine-turning of tooth top cylindrical machining and rough-turning of end faces and bores also demonstrated high efficiency and stability. In wind turbine bearing machining, the parameters were adjusted and the BN-H200 PCBN inserts from Halnn were used, which significantly improved the productivity and surface finish. >>

Halnn CBN tools provide excellent solutions for hard turning wind turbine gears, solving problems such as CBN tool broken and low machining efficiency, and recommending the use of BN-H200 RNGN090300 CBN tools can improve machining efficiency. Wind turbine gear machining improvement in three cases, the use of Halnn CBN tools can improve machining efficiency, surface quality, machining time, etc.. >>

Halnn PCBN inserts provide excellent solutions for rough turning of inner ring ribs of wind turbine bearings, solving the customer's original CBN inserts are not wear-resistant, machining super poor and other problems.At the same time, after recommending the use of BN-H200RCGX CBN inserts, With high wear resistance and strong impact resistance, the cost can be reduced by 60%. >>

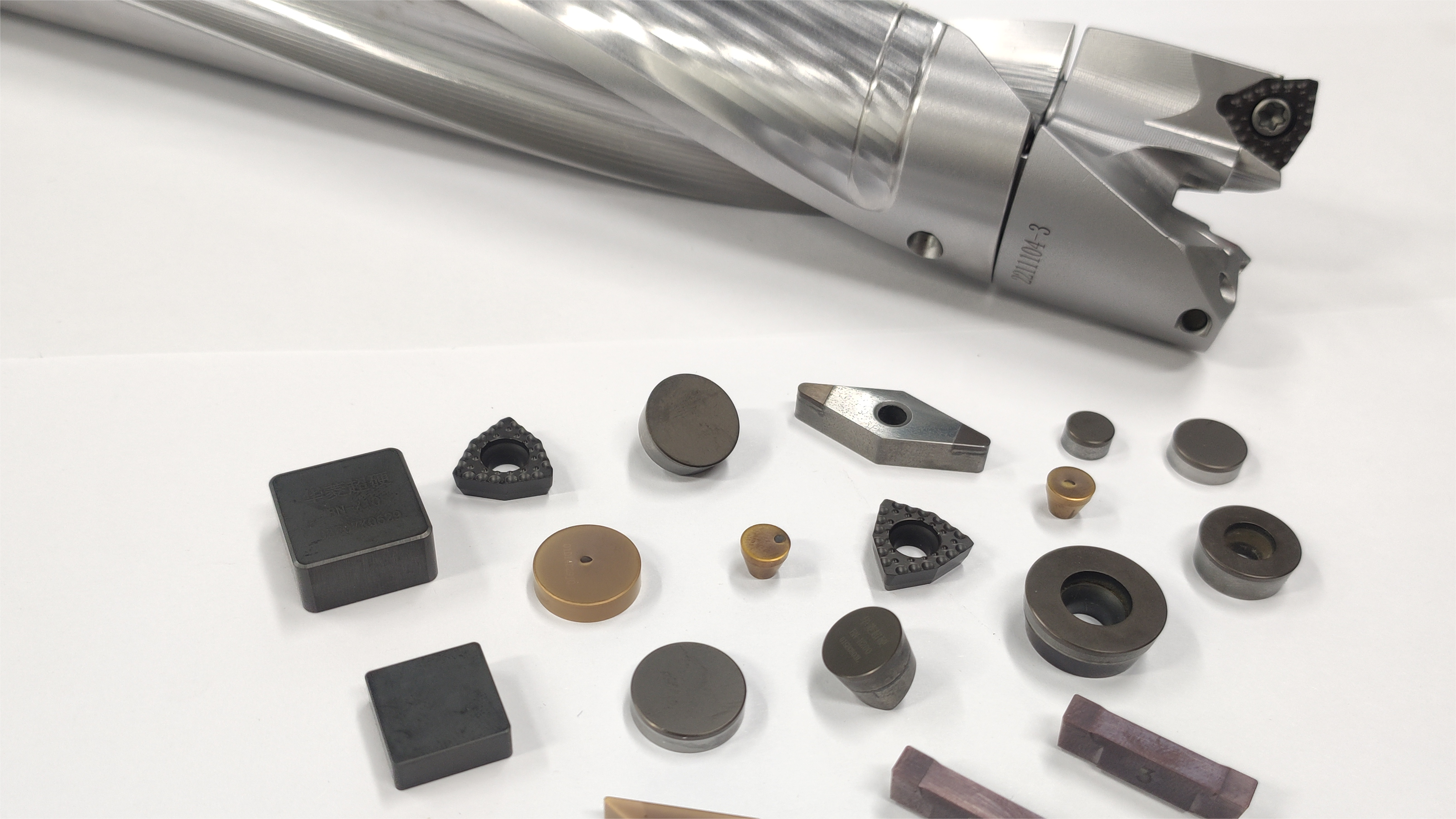

Most of parts in this field are made of hardened steel with HRC58-62. Therefore, BN-H series of full face PCBN inserts are specially designed.To address the different machining requirements, RNGN and CNGA PCBN inserts were recommended for gear end surface, inner bore and outer surface. >>

Investment in the wind power equipment manufacturing industry is high, but the machining of wind turbine bearing parts faces problems such as large size, weight, complex structure and precision maintenance. Halnn adopts innovative tool design and manufacturing technology, launches PCBN inserts series with high hardness and high wear resistance, launches PCBN inserts with special geometric designs for different parts, and provides non-standard customized products, which successfully improves cutting efficiency and machining quality and provides reliable solutions for the development of wind power industry. >>

With the improvement of the rolling speed, the requirement for the hardness of mill roll is higher. Now, the main materials for rebar mill rolls are high speed steel and tungsten carbide. For the high-speed steel mill rolls,the notching tools and engraving tools of tungsten carbide are generally processed on the relevant CNC milling machine dedicated to the roll. They have required wear resistance and impact resistance for notching and engraving. For the grinding process of high-speed steel mill rolls, Halnn provides CBN grinding wheels to improve the efficiency. For the hardest tungsten carbide roller ring, we need to use CBN/PCD tools and CVD diamond tools to notch, engrave and grind such high-hardened materials. >>

carbide roll machining: carbide roll hardness HRC84.5-85, using Halnn CBN tools HLCBN isnerts, the tool life is 4 times higher than that of an imported CBN tools. >>

We are looking for business partners to establish dealerships or become authorized distributors. Join our network and embark on a journey of growth and success with Halnn. You can contact us via market@halnn-group.com or click here .

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.