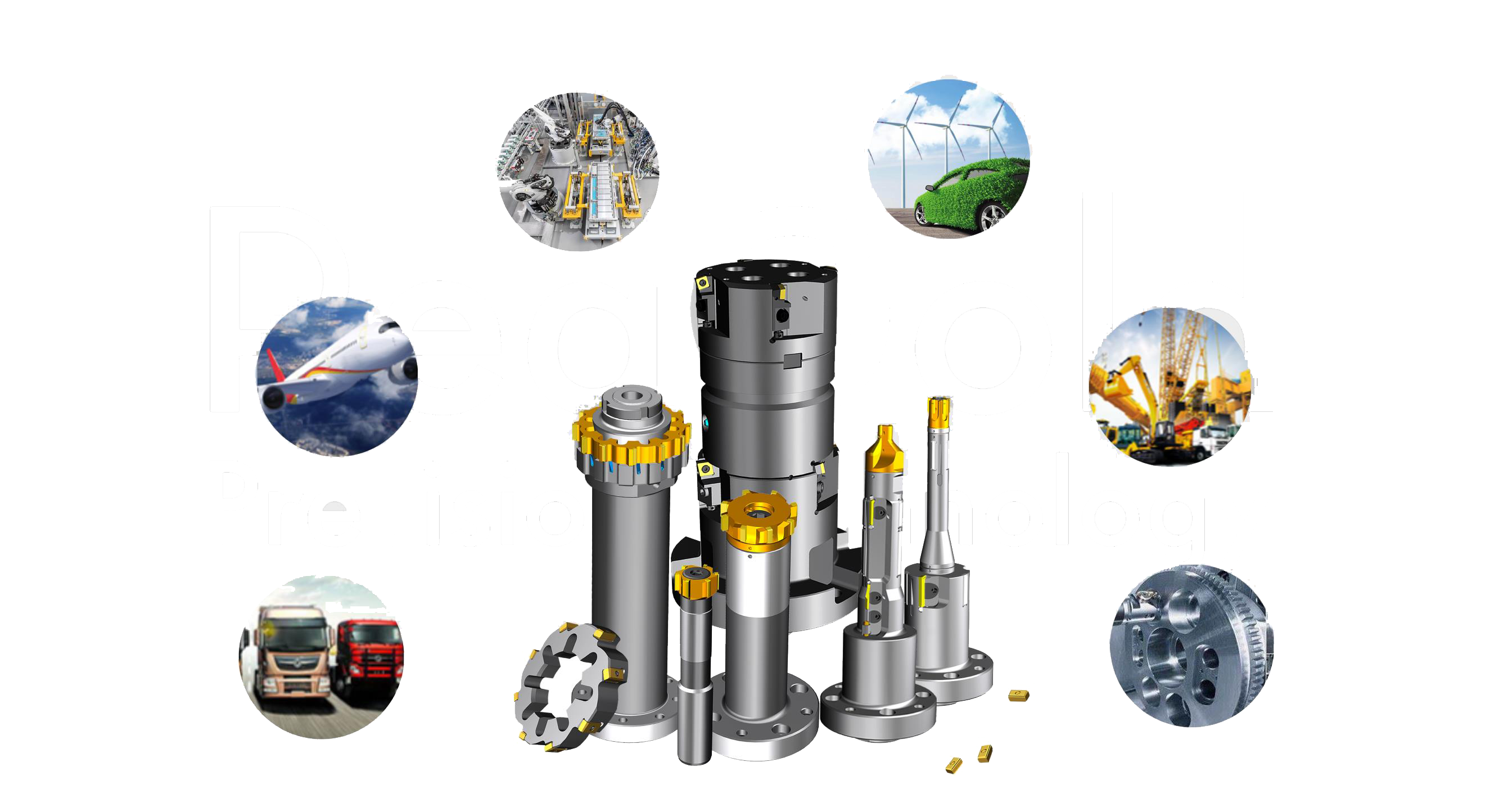

Our Carbide Reamers are designed to deliver exceptional performance, ensuring high-quality hole-making for hydraulic components. Whether you’re looking for enhanced accuracy or extended tool life, Halnn’s Carbide Reamers are the ideal solution for your machining needs.

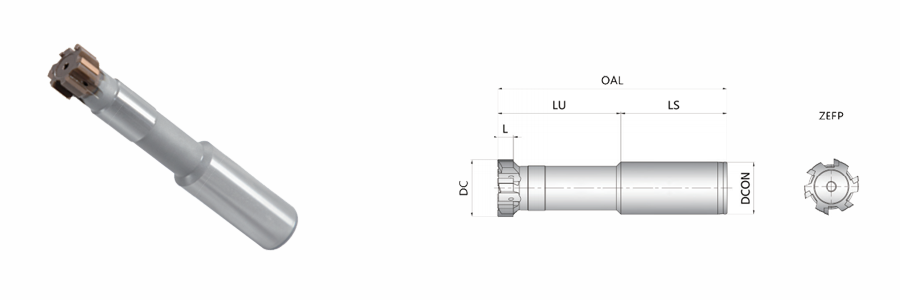

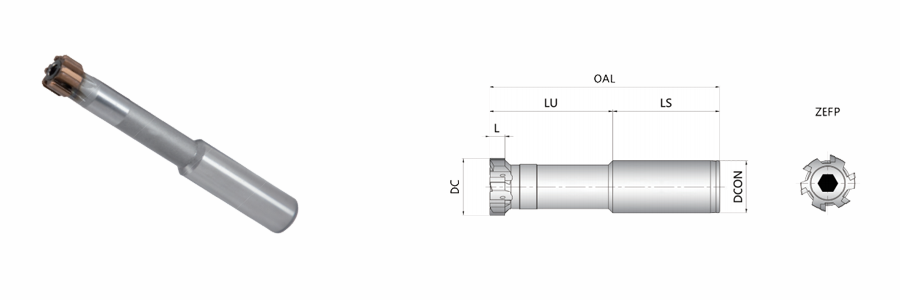

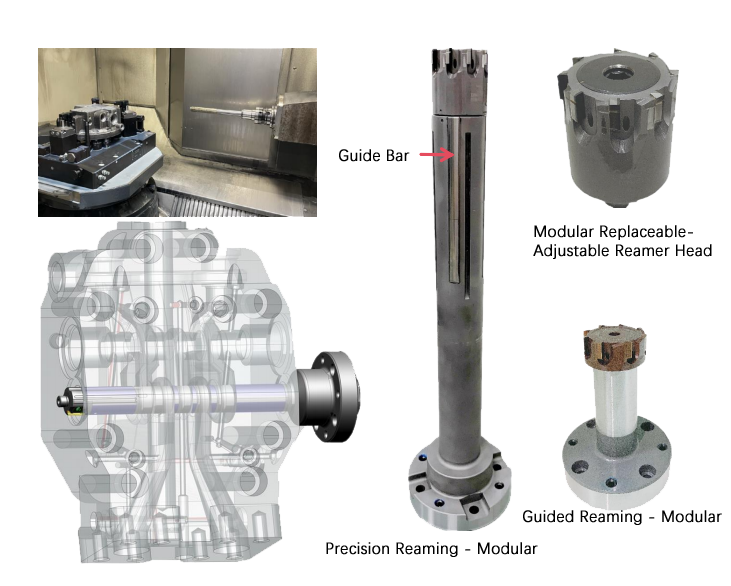

HGP Reamer

· High machining precision

· Meets requirements for roundness and cylindricity tolerances

· Guide bar support

· Replaceable inserts

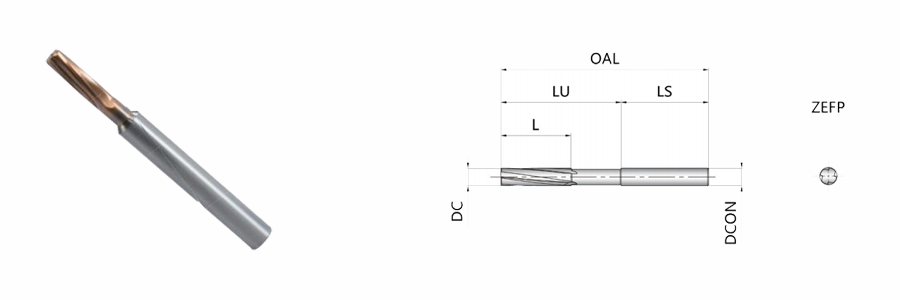

| Solid Carbide Reamer |  |

| S Series Reamer |  |

| E Series Adjustable Reamer |  |

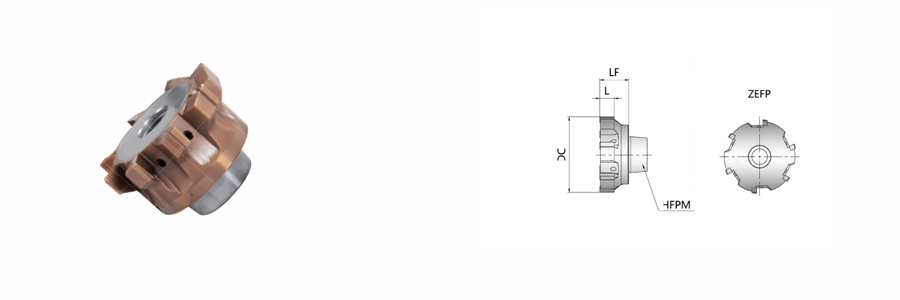

| H Series Reamer Head |  |

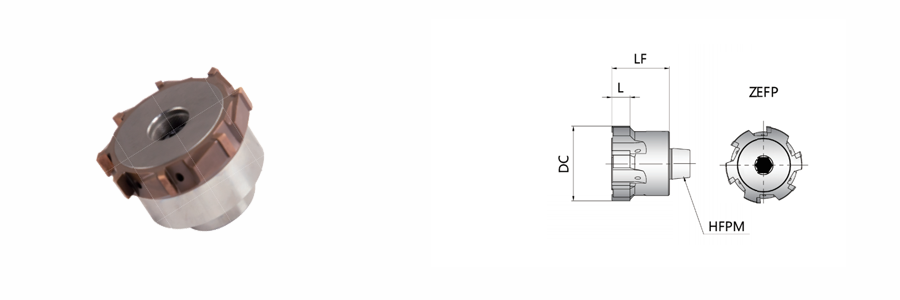

| K Series Adjust Reamer Head |  |

|  |

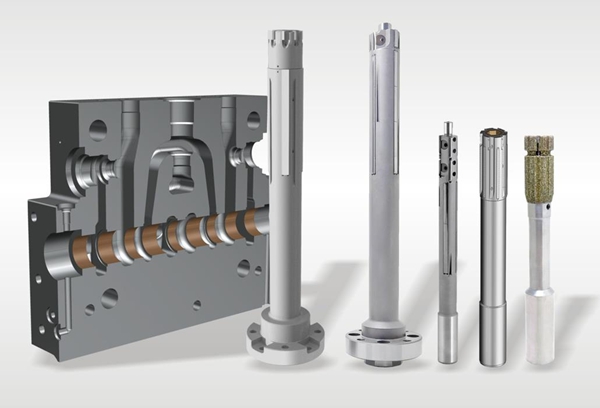

| Valve body/valve block(HGP single blade reamer) | High pressure piston pump/rotor (HCP reamers) |

Specifications:

·Diameter: D39.96 ± 0.002 mm

·Material: Ductile Iron QT400

·Surface Roughness: Ra 1.6

·Cylindricity: 0.01 mm

Solution Provided:

Halnn offered a modular adjustable multi-blade reaming solution.

Machining Parameters:

·Cutting Speed (Vc): 120 m/min

·Spindle Speed (S): 1000 rpm

·Feed Rate (F): 600 mm/min

·Surface Roughness Requirement: Ra 1.6

·Cylindricity: 0.008 mm

Results:

·Achieved stable machining and high-efficiency cutting

·Manufacturing precision reached H5 tolerance

This successful case demonstrates Halnn's capability in providing high-precision, efficient solutions for complex machining tasks, ensuring optimal performance and quality for our clients.

Mode:RNMN RCMX-V RCMX-Y PCD Type:BN-K1,BN-S20,CDW010 Application:Heavy Machining

Mode: Type: Application:Hydraulic industry

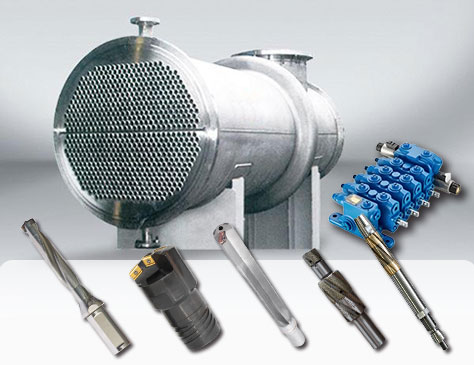

Mode:Drilling, Boring, Reaming Type:Gun Drills, Solid Carbide Drill Application:Hole Machining

Mode:Turning, Milling, Hole-making Type:PCBN Insert, PCD Tools Application:Auto Parts

We are looking for business partners to establish dealerships or become authorized distributors. Join our network and embark on a journey of growth and success with Halnn. You can contact us via market@halnn-group.com or click here .

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.