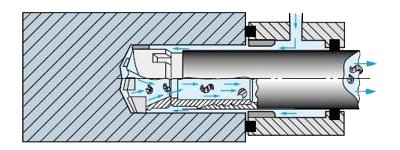

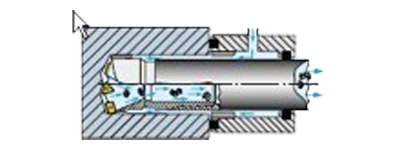

Halnn’s BTA Drill is a high-performance deep hole drilling tool designed to meet the most demanding requirements for deep hole machining. Utilizing the advanced BTA-System (single tube system), this tool offers exceptional accuracy, efficiency, and reliability for applications requiring external coolant supply and internal chip evacuation. Ideal for specialized deep hole drilling machines, our BTA drill ensures superior performance in industries such as oil and gas, aerospace, and heavy machinery.

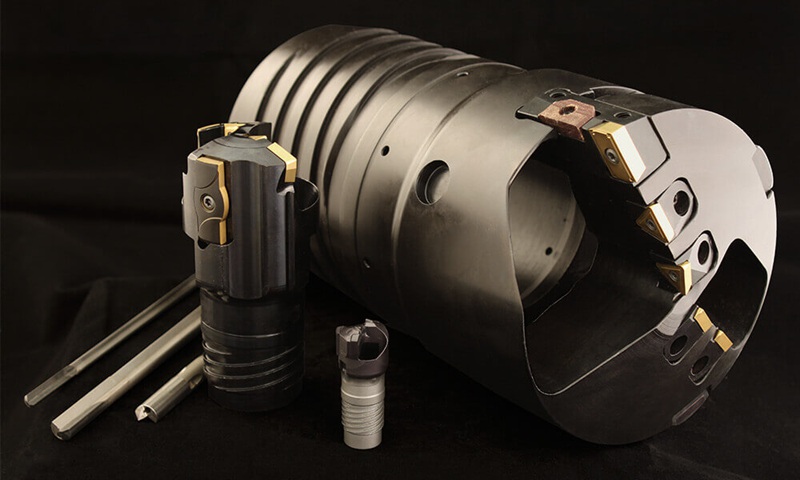

Comparison Between Brazed BTA Drill and Indexable BTA Drill

| Brazed Carbide BTA Drill | Indexable Carbide BTA Drill |

|  |

| Short tool life and high raw material consumption | Long tool life and low raw material consumption |

High-temperature brazing reduces carbide insert performance, introduces welding stress, and results in poor cutting performance | Uses high-performance carbide grades with excellent cutting performance |

| Low cutting parameters and high power consumption during machining | High cutting parameters and low power consumption during machining |

High cost for surface modification treatment; some products are not suitable for such treatment | Surface modification treatment on inserts enhances cutting efficiency and tool life |

Poor consistency and stability in chip formation and evacuation, but high outer diameter accuracy | Reliable and stable chip formation and evacuation, though with lower outer diameter accuracy |

Mode:CBN Inserts Type:BN-S300,BN-S30 Application:Brake Disc/Drum

Mode:Milling,Drilling,Reaming Type:PCD Tools,Carbide Tools Application:Aerospace Field

Mode:RNMN RCMX-V RCMX-Y PCD Type:BN-K1,BN-S20,CDW010 Application:Heavy Machining

Mode:Turning, Milling, Drilling, Boring Type:Crown Drill, PCD Inserts Application:Wind Energy

We are looking for business partners to establish dealerships or become authorized distributors. Join our network and embark on a journey of growth and success with Halnn. You can contact us via market@halnn-group.com or click here .

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.