GLC, a subsidiary brand of Halnn Group, specializes in the final stage of precision engineering—precision grinding. Leveraging global technological collaboration and exchange, GLC focuses on precision manufacturing sectors such as automotive production, wind energy, and semiconductors. It demonstrates exceptional performance in grinding applications for camshafts/crankshafts, gear shafts, and motor shafts, offering notable advantages in high efficiency, high precision, and superior surface quality. With reliable performance, GLC has got a good market reputation.

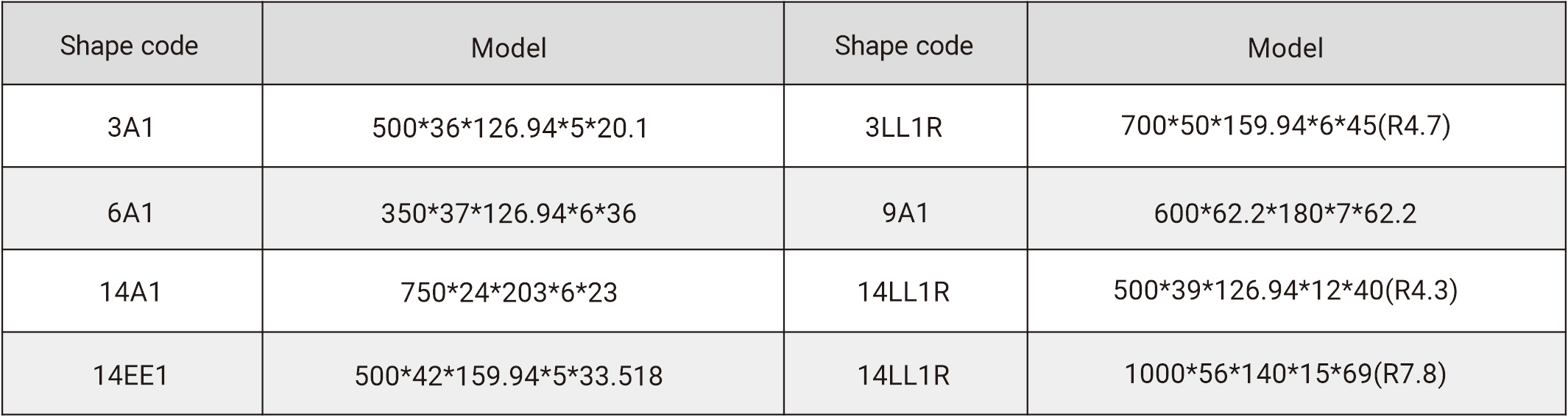

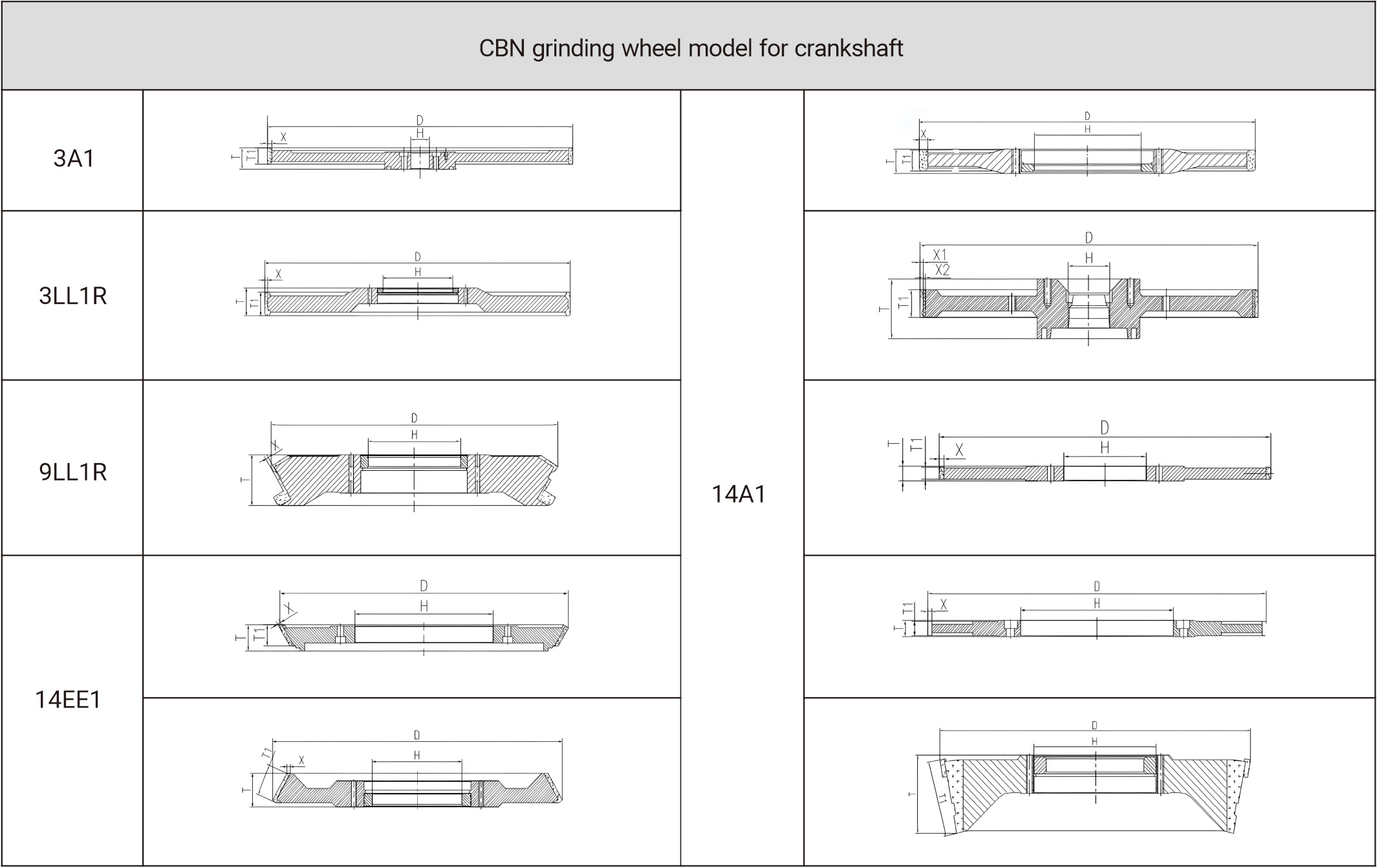

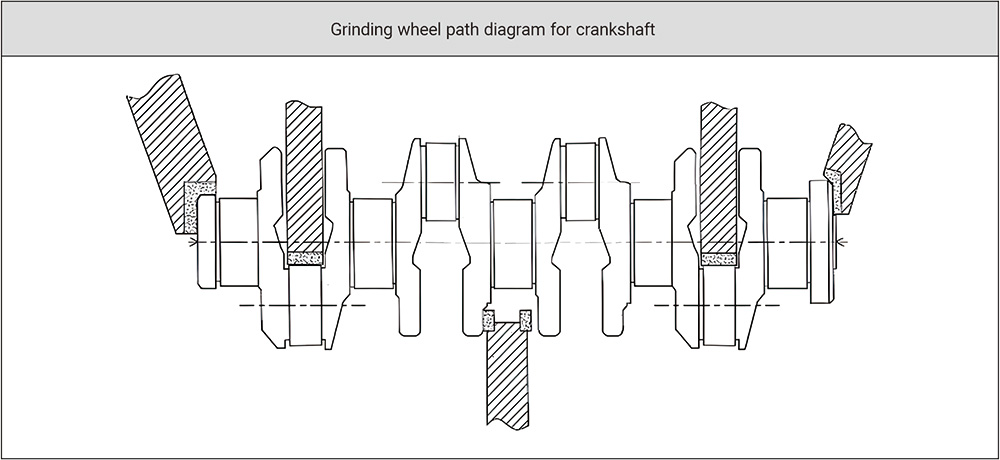

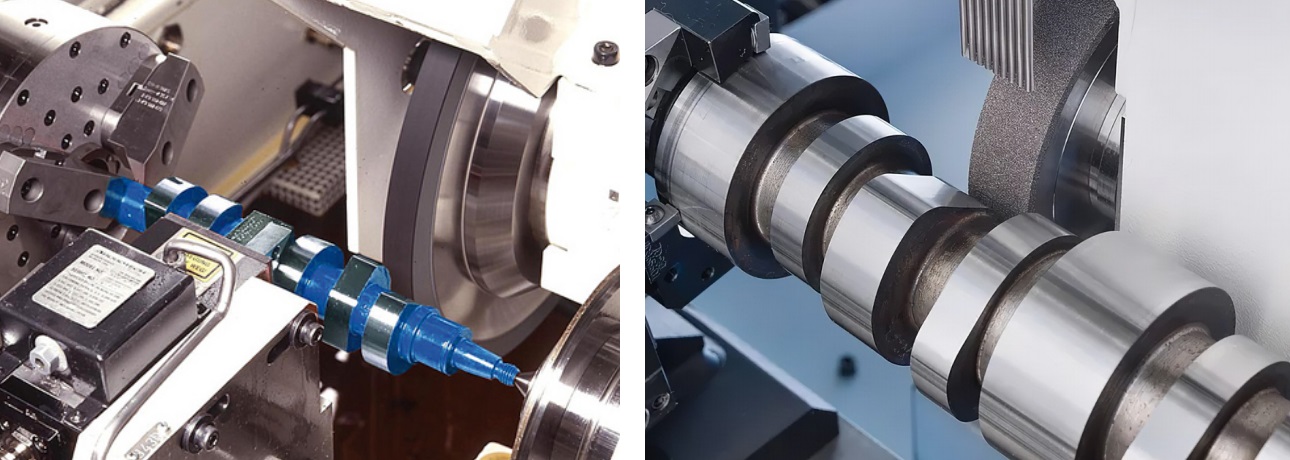

1. Specification of CBN grinding wheel for crankshaft grinding

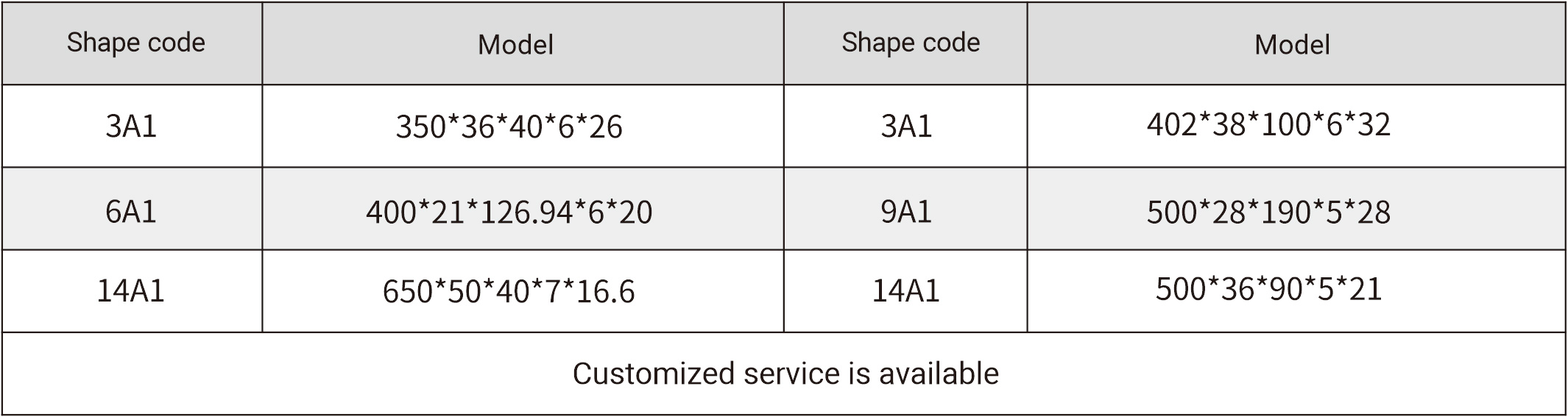

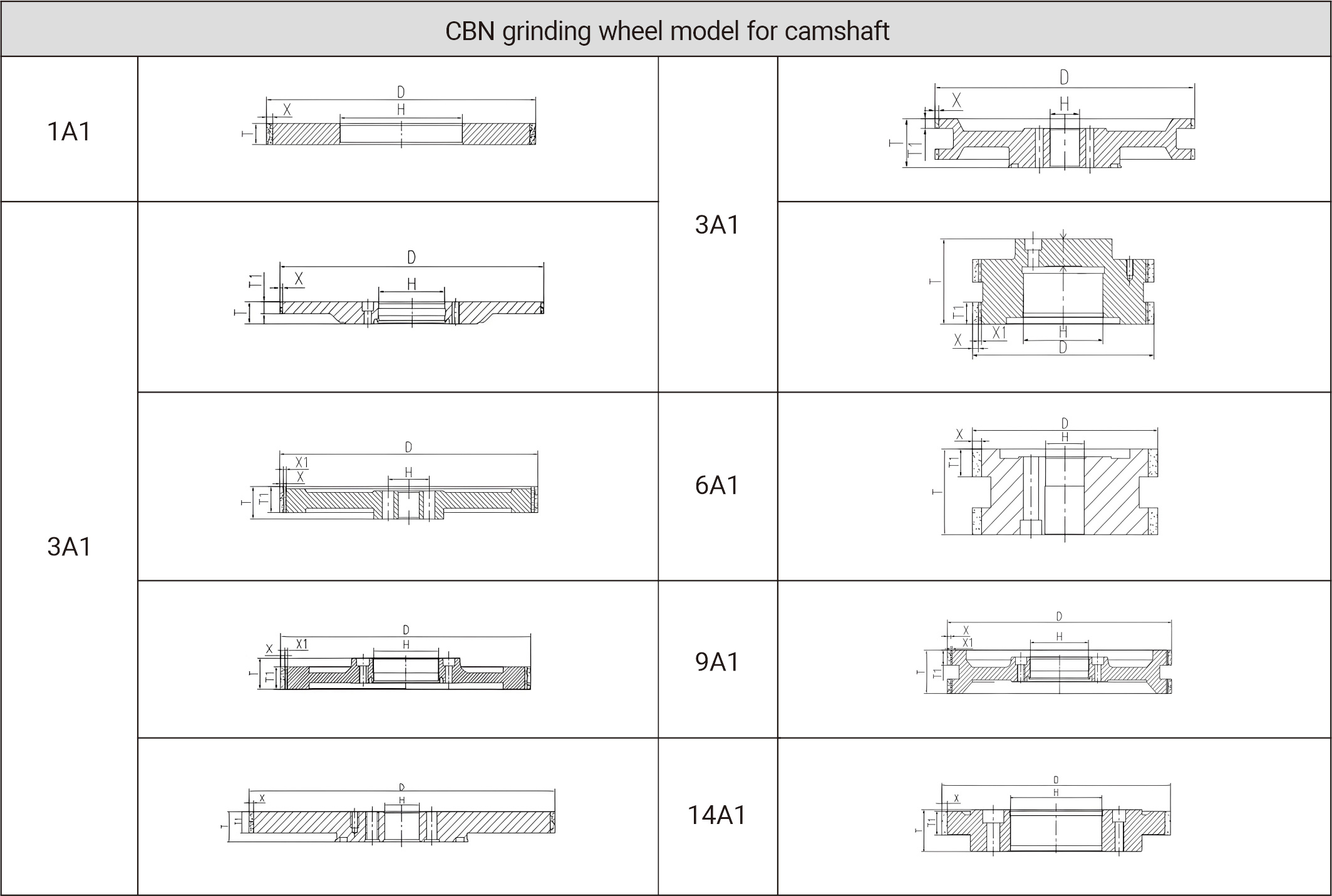

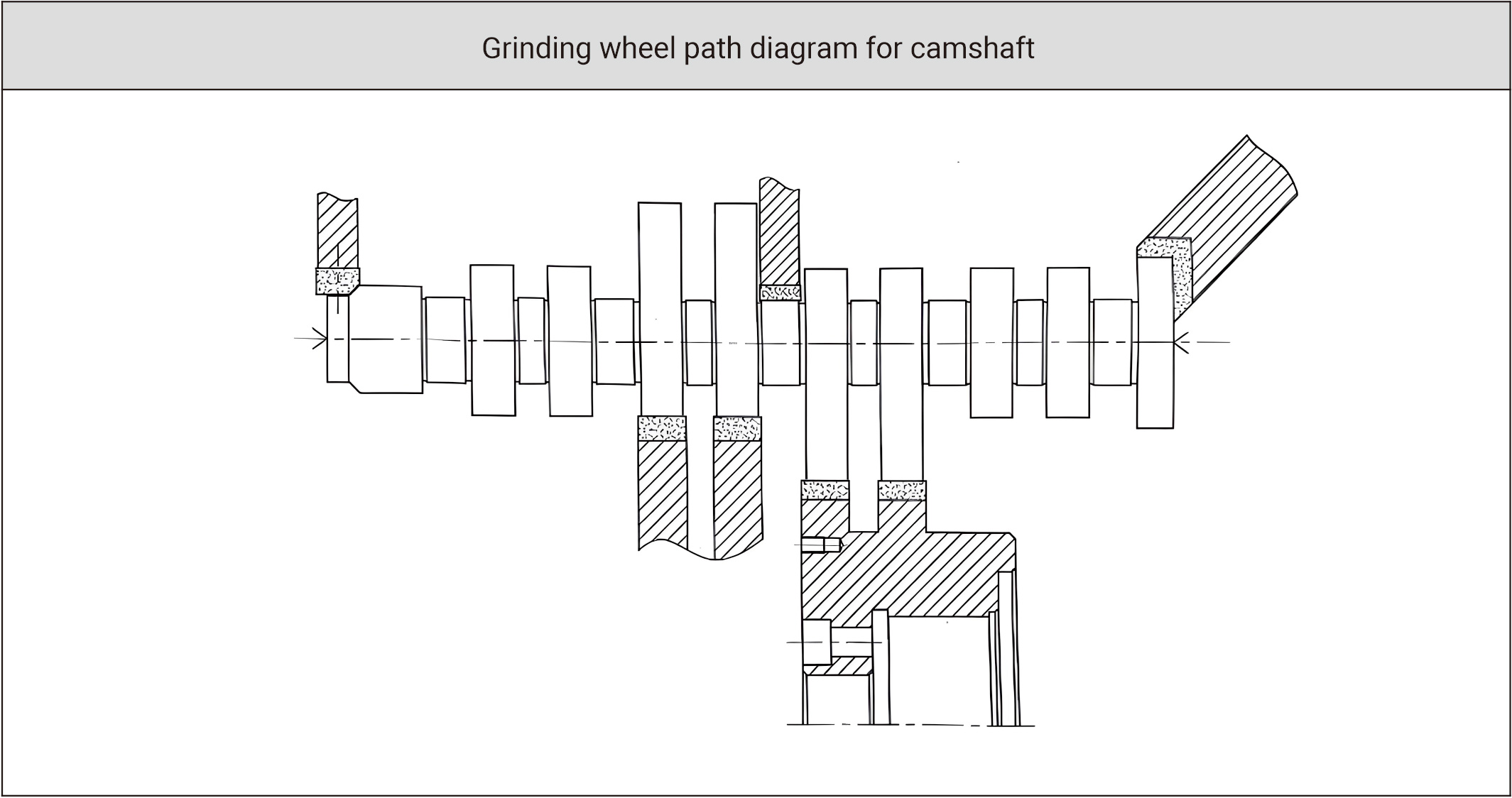

2. Specification of CBN grinding wheel for camshaft grinding

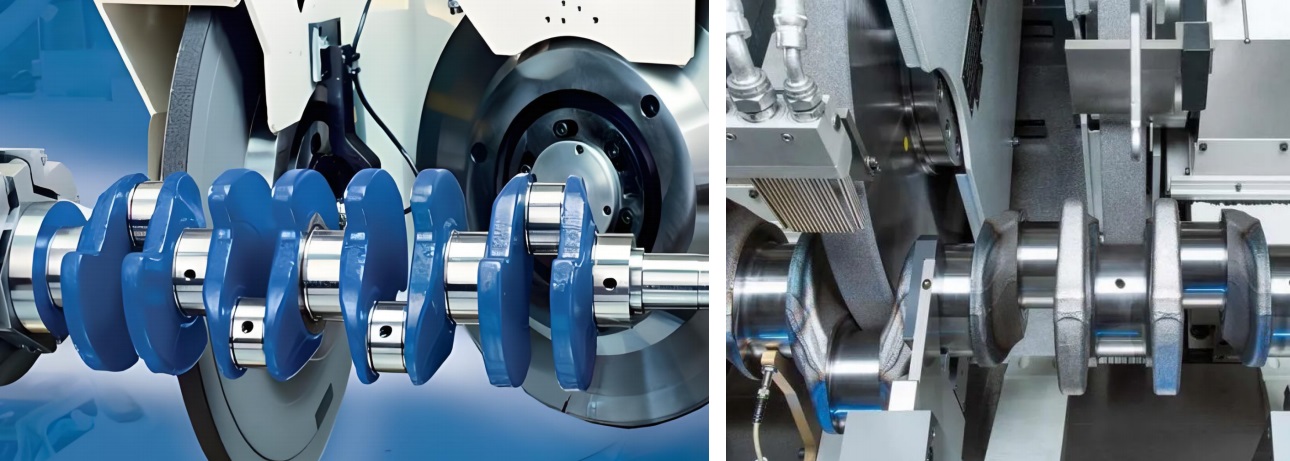

1. CBN grinding wheel for crank shaft

Suitable for the grinding of crank shaft main journals, connecting rod journals, and thrust faces in automotive engines. It offers high grinding efficiency, excellent wear resistance, and chemical stability, with a wheel speed of 80 m/s to 160 m/s.

2. CBN grinding wheel for cam shaft

Suitable for the grinding of camshaft lobes, main journals, and oil pump gears in automotive engines. Features uniform porosity and low grinding temperatures, delivering high workpiece accuracy and superior surface finish. Wheel speed: 80 m/s to 160 m/s.

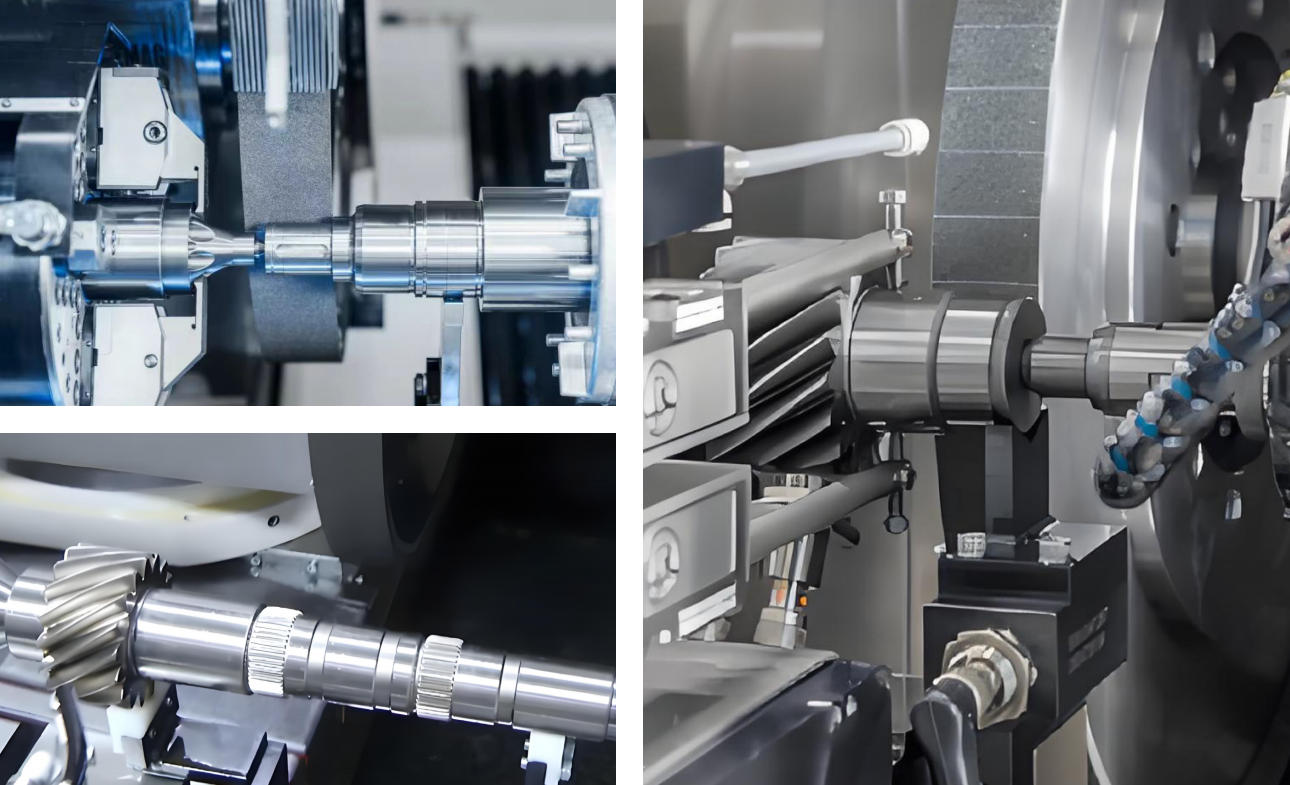

3. CBN grinding wheel for gear shaft

Application Field: Grinding of automotive engine transmission shafts (including outer diameter, thrust faces, shoulders, splines, etc.).

Workpiece Materials: 40Cr, 20CrMnTi, etc.

Applicable Grinding Machines: Studer, Mörl, Buderus, Henbo, etc.

Grinding Wheel Characteristics: High cutting efficiency, superior material removal rate, minimal burn risk, and versatility across multiple grinding operations.

Mode:Turning, Milling, Drilling, Boring Type:Crown Drill, PCD Inserts Application:Wind Energy

Mode:Drilling, Boring, Reaming Type:Gun Drills, Solid Carbide Drill Application:Hole Machining

Mode:Milling,Drilling,Reaming Type:PCD Tools,Carbide Tools Application:Aerospace Field

Mode:CBN Inserts Type:BN-S300,BN-S30 Application:Brake Disc/Drum

We are looking for business partners to establish dealerships or become authorized distributors. Join our network and embark on a journey of growth and success with Halnn. You can contact us via market@halnn-group.com or click here .

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.