Halnn's CBN Milling Inserts are the ultimate solution for machining hardened steels and other tough materials. Engineered for superior wear resistance and precision, our CBN inserts ensure high productivity and long-lasting performance in challenging milling applications. Designed to meet the rigorous demands of modern manufacturing, Halnn’s CBN Milling Inserts deliver reliability and excellence in every cut.

CBN Milling inserts

|  |  |  |  |  |

SNFN | CNFN | RNFN | SNEN | SNEX | RNEN |

|  |  |  |  | |

OPHN | RDMW | APMT | SEET | Ball screw special milling inserts |

Halnn CBN Milling Insert Grades

| Halnn CBN Grade | Suited materials | Machining Condition | Typical application |

BN-K1 | Chilled cast iron, high nickel-chromium alloy, high-hardness alloy cast iron | Rough machining | Alloy cast iron rolls, slurry pumps, wear-resistant castings, etc. |

BN-S20 | Hardened steel, heat-resistant and wear-resistant steel, high manganese steel | Rough and semi-finish machining | HSS rolls, lead screws, wind power bearings |

BN-S200 | Hardened steel, high-temperature alloys | Finish machining | Wind power bearings |

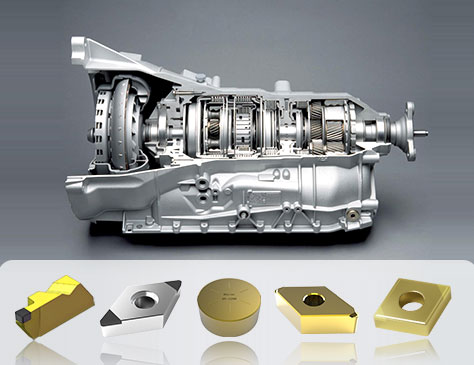

BN-S300 | Gray cast iron | Rough and finish machining | Brake discs, brake drums, cast iron engines, transmissions, cylinder liners, etc. |

BNK30 | Gray cast iron, iron-based sintered alloys | Semi-finish and finish machining | Brake discs, brake drums, cast iron engines, transmissions |

BN-H10 | Hardened steel, high-strength alloys | Finish machining | Bearings, CV joints, gears, gear shafts, high-hardness parts |

BN-H21 | Hardened steel | Finish machining | Bearings, CV joints, gears, gear shafts, molds |

| BN-K10 | Gray cast iron, powder metallurgy | Finish machining | Valve seat rings, engine cylinder bores, powder metallurgy parts |

Halnn CBN Inserts Cutting Parameters for reference

Machining Materials | Machining Type | Recommended cutting parameters | CBN insert Grade | ||

Cutting speed VC(m/min) | Cutting Depth ap (mm) | Feed Rate Fr(mm/r) | |||

High hardness cast iron (Hardness: HRC35-68) | Roughing | 35-120 | 1-10 | 0.15-1.0 | BN-K1 |

Finishing | 60-200 | ≤1 | 0.05-0.35 | BN-K10,BN-H10 | |

Hardened steel (Hardness≥HRC45) | Roughing | 50-150 | 1-10 | 0.1-0.5 | BN-S10, BN-S20 |

Finishing | 90-250 | ≤1 | 0.05-0.35 | BN-H10,BN-H21,BN-S200 | |

Grey cast iron | Roughing | 400-1200 | 1-10 | 0.2-1.0 | BN-S300 |

Finishing | 600-2000 | ≤1 | 0.05-0.3 | BNK30,BN-K10 | |

Halnn CBN Inserts Characteristics

Insert Grade | Binder | CBN Content(%) | Granularity(μm) | Hardness(HV) |

BN-K1 | TIC | 90 | 8-12 | 3000-3250 |

BN-S10 | AL, TiN | 80 | 4-10 | 3100-3300 |

BN-S20 | TIN | 76 | 4-6 | 2900-3100 |

BN-S200 | TIN | 60 | 2-4 | 2800-3000 |

BN-S300 | AL, TIC | 97 | 4-6 | 3400-3600 |

BN-H10 | TIN | 50 | ≤1 | 2700-2800 |

BN-H21 | AL, TINC | 60 | 1-2 | 2600-2800 |

BN-K10 | Ti, Co | 95 | ≤2 | 3300-3500 |

BNK30 | Si, TIC | 97 | 2-4 | 3400-3600 |

Halnn CBN Inserts Cutting Conditions

CBN Content | Insert Grade | Cutting Depth | Condition |

High Content | BN-K1 | 1-10mm | Interrupt-Continuous |

BN-S300 | ≤2mm | Continuous | |

BNK30 | ≤1.5mm | Continuous | |

BN-K10 | ≤0.5mm | Continuous | |

Low Content | BN-S20 | 1-10mm | Interrupt-Continuous |

BN-S200 | ≤1mm | Continuous | |

BN-H10 | ≤0.5mm | Continuous~Semi-Interrupt | |

BN-H21 | ≤0.5mm | Semi-Interrupt~Heavy Interrupt |

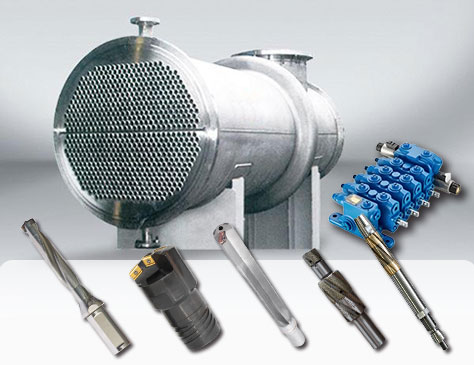

Mode:Drilling, Boring, Reaming Type:Gun Drills, Solid Carbide Drill Application:Hole Machining

Mode:CBN tools Type:Solid CBN Insert,PCBN Insert Application:Hardened Steel

Mode:Turning, Milling, Drilling, Boring Type:Crown Drill, PCD Inserts Application:Wind Energy

Mode:CBN Inserts Type:BN-S300,BN-S30 Application:Brake Disc/Drum

We are looking for business partners to establish dealerships or become authorized distributors. Join our network and embark on a journey of growth and success with Halnn. You can contact us via market@halnn-group.com or click here .

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.