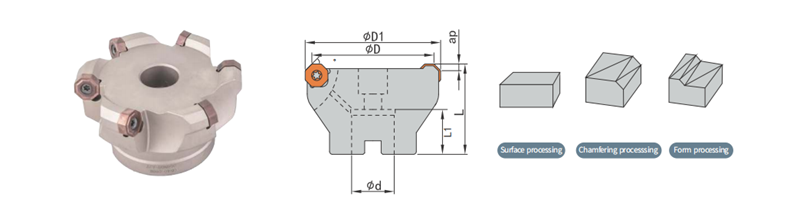

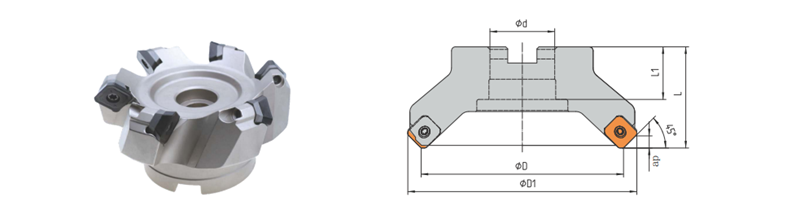

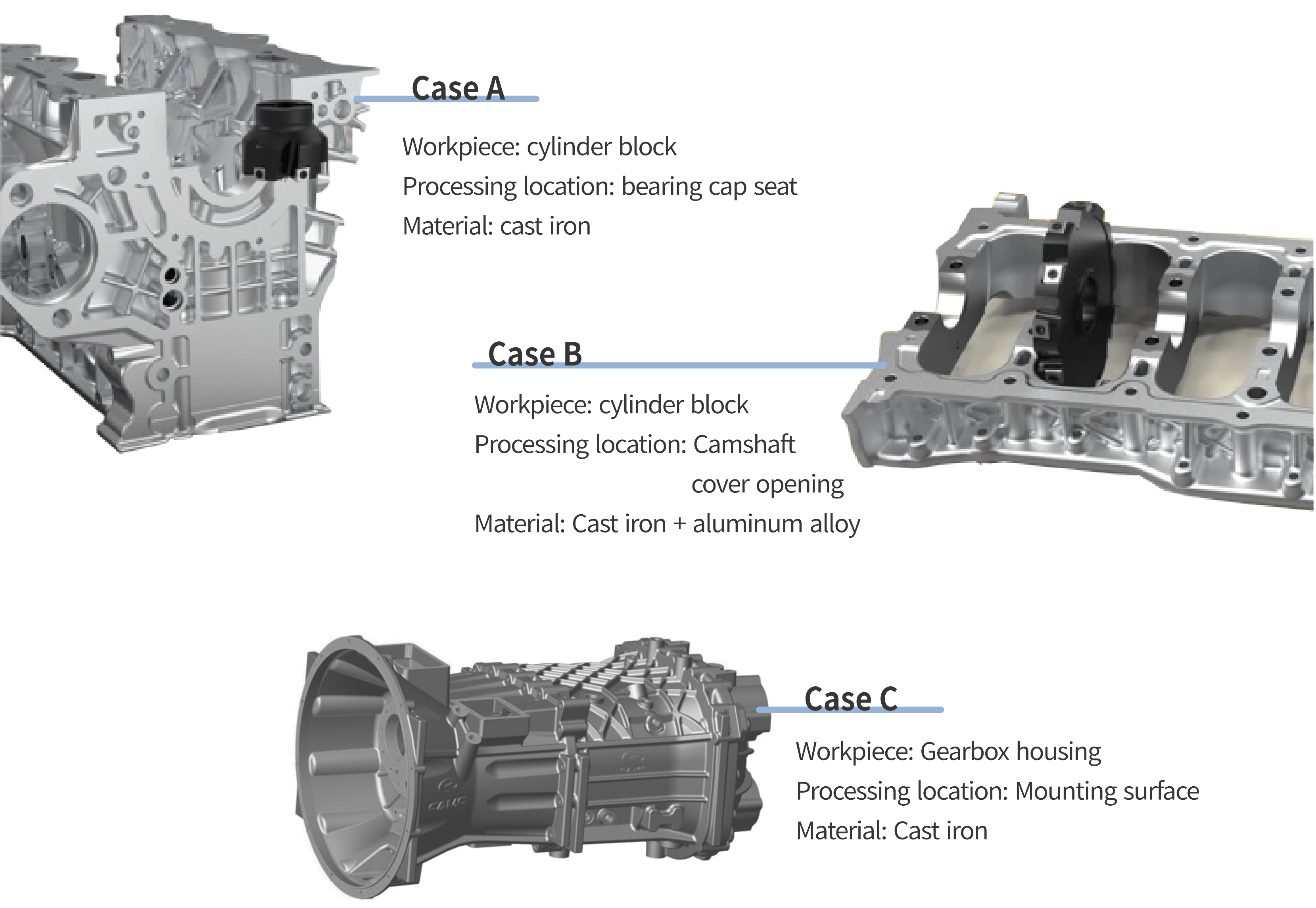

The Carbide Face Milling Cutter is a high-efficiency precision milling tool designed for machining steel, cast iron, stainless steel, aluminum alloys, and other materials. Featuring premium carbide inserts, it offers excellent wear resistance and impact toughness, ensuring stable and efficient cutting with extended tool life.

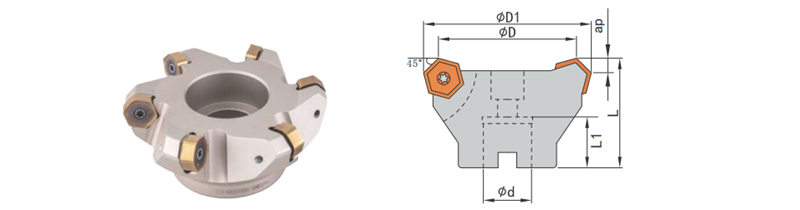

ON series face milling cutter

|  |

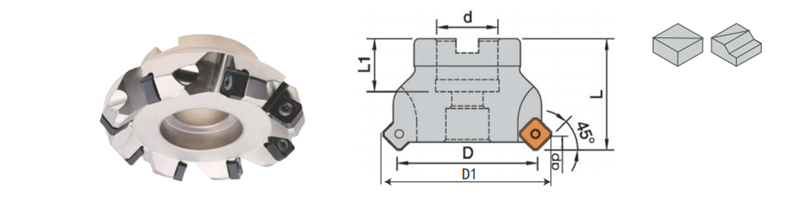

HN45 series face milling cutter

|  |

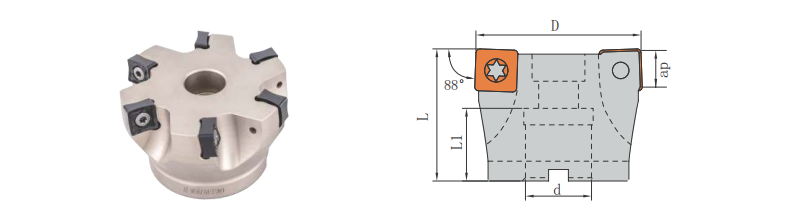

4033 series face milling cutter

|  |

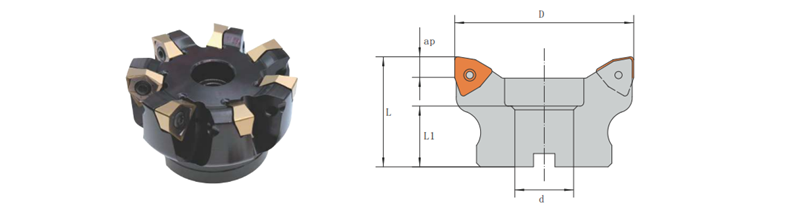

4048 series face milling cutter

|  |

CMF series face milling cutter

|  |

ASX445 series face milling cutter

|  |

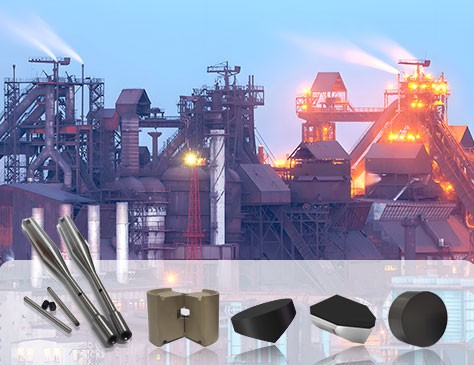

Mode:RNMN RCMX-V RCMX-Y PCD Type:BN-K1,BN-S20,CDW010 Application:Heavy Machining

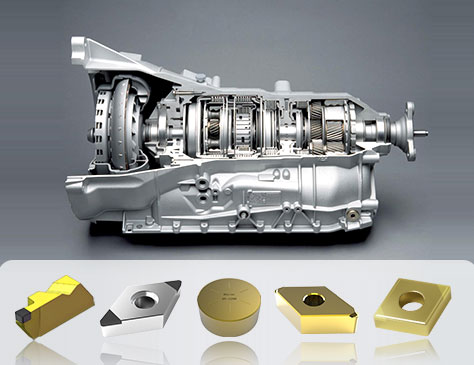

Mode: Type: Application:Hydraulic industry

Mode:CBN tools Type:Solid CBN Insert,PCBN Insert Application:Hardened Steel

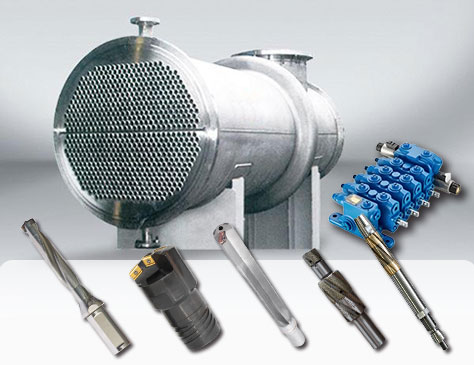

Mode:Drilling, Boring, Reaming Type:Gun Drills, Solid Carbide Drill Application:Hole Machining

We are looking for business partners to establish dealerships or become authorized distributors. Join our network and embark on a journey of growth and success with Halnn. You can contact us via market@halnn-group.com or click here .

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.