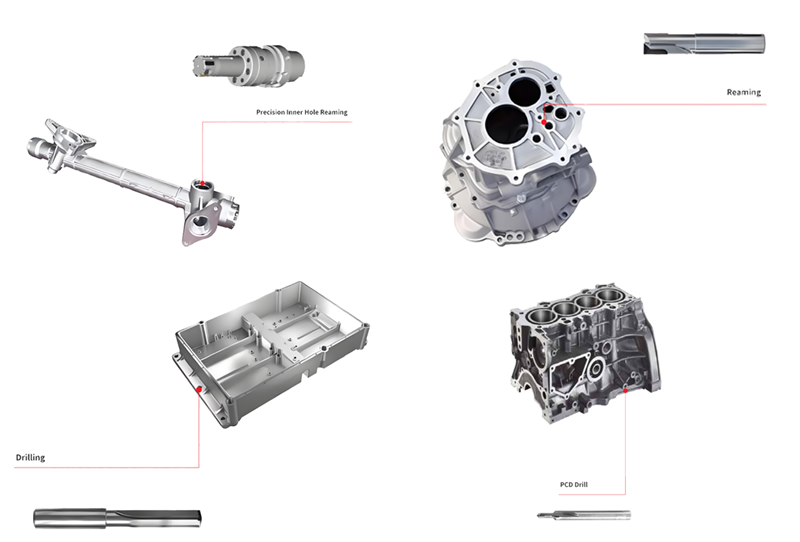

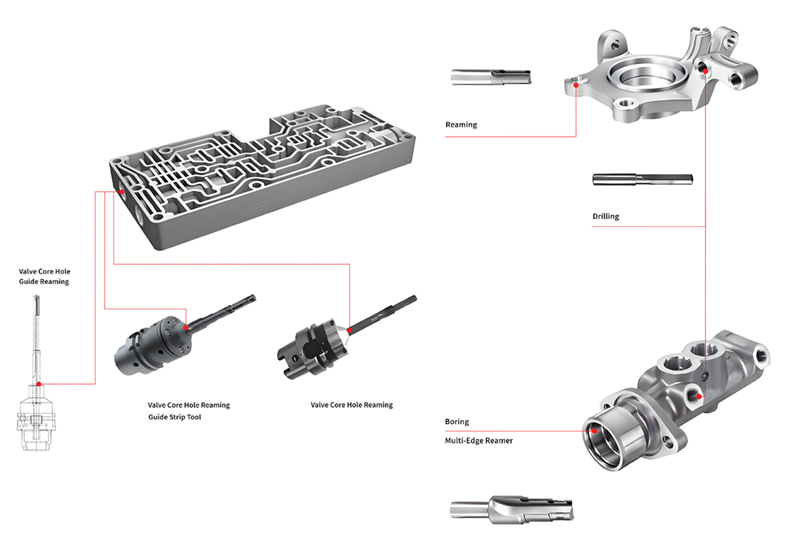

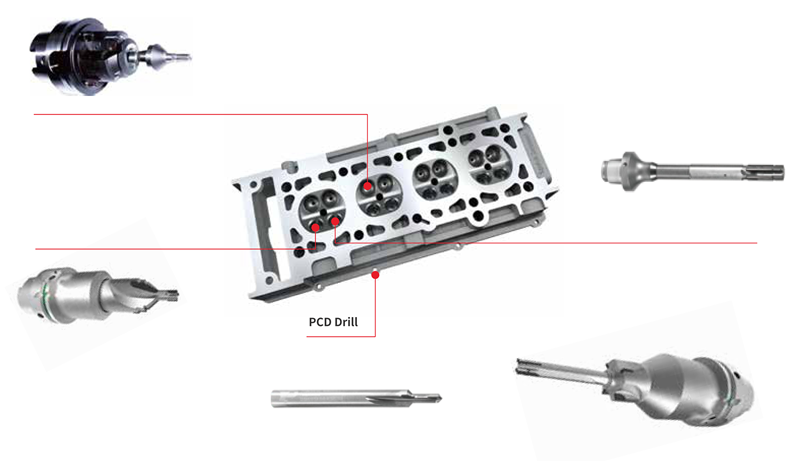

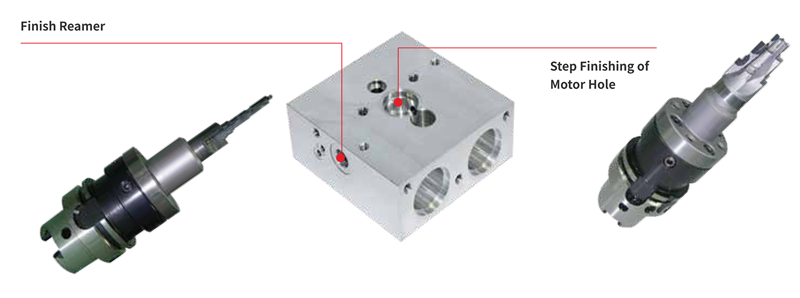

Halnn’s PCD (Polycrystalline Diamond) drills and reamers are engineered to meet the high-performance demands of the automotive industry. Designed for precision machining of lightweight materials and alloys, these tools ensure superior accuracy, long tool life, and exceptional surface quality, making them the ideal choice for manufacturing critical automotive components.

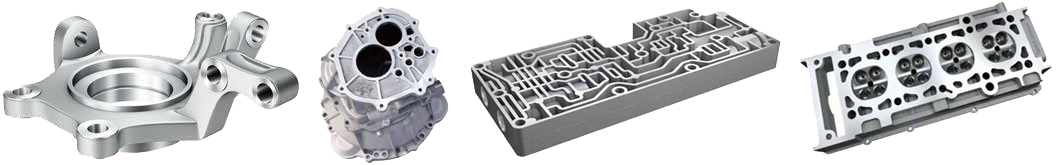

Automotive:

(1)Automotive cylinder head

(2)Automotive hydraulic parts: AT valve body, regulator valve body

(3)Steering spool, transmission housing

(4)Other aluminium alloy parts

Mode:RNMN RCMX-V RCMX-Y PCD Type:BN-K1,BN-S20,CDW010 Application:Heavy Machining

Mode:Drilling, Boring, Reaming Type:Gun Drills, Solid Carbide Drill Application:Hole Machining

Mode:Turning, Milling, Hole-making Type:PCBN Insert, PCD Tools Application:Auto Parts

Mode:Turning, Milling, Drilling, Boring Type:Crown Drill, PCD Inserts Application:Wind Energy

We are looking for business partners to establish dealerships or become authorized distributors. Join our network and embark on a journey of growth and success with Halnn. You can contact us via market@halnn-group.com or click here .

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.