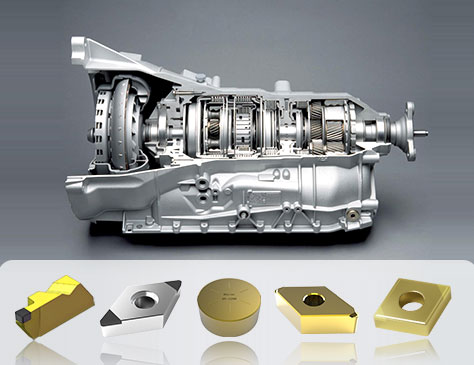

At Halnn, we specialize in manufacturing high-performance Standard PCD Face Milling Tools designed for precision machining of non-ferrous materials. Halnn Tools PCD face milling cutter is designed for machining aluminum alloys and other non-ferrous metals, offering high performance with a lightweight structure.

·From Roughing to Finishing in One Pass – Capable of completing rough and finish machining in a single pass for cutting depths up to 3mm.

·Durable & Lightweight Cutter Body – Made from a special aluminum alloy, providing enhanced strength while weighing only 40% of a steel cutter body, achieving significant weight reduction.

·Surface Hard Coating for Corrosion Resistance – Reduces spindle load during high-speed rotation, enhances tool life, and minimizes tool change time.

·Simple Runout Adjustment – Features an easy-to-use external adjustment mechanism, ensuring runout accuracy within 10μm.

·Various Cutting Angles Available – Multiple insert geometries are available to suit different machining conditions.

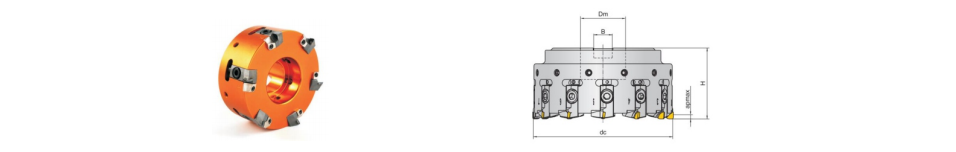

Dense tooth type

| Type | ap max | Dimension(mm) | Teeth Z | Cartridge | Cooling | |||

| dc | Dm | B | H | |||||

| HPVF63R8P22* | 5 | 63 | 22 | 10.4 | 48 | 8 | HPV-*** | ﹢ |

| HPVF80R8P27A | 5 | 80 | 27 | 12.4 | 50 | 8 | ||

| HPVF100R10S32AL | 5 | 100 | 32 | 14.4 | 50 | 10 | ||

| HPVF125R12S40AL | 5 | 125 | 40 | 16.4 | 63 | 12 | ||

| HPVF160R18T40AL | 5 | 160 | 40 | 16.4 | 63 | 18 | ||

| HPVF200R24T60AL | 5 | 200 | 60 | 25.7 | 63 | 24 | ||

| HPVF250R30T60AL | 5 | 250 | 60 | 25.7 | 63 | 30 | ||

| HPVF315R38U60AL | 5 | 315 | 60 | 25.7 | 80 | 38 | ||

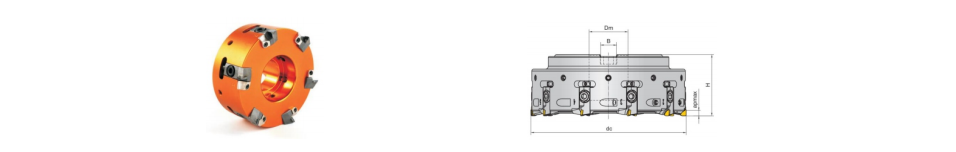

Sparse tooth type

| Type | ap max | Dimension(mm) | Teeth Z | Cartridge | Cooling | |||

| dc | Dm | B | H | |||||

| HPVF63R8P22* | 5 | 63 | 22 | 10.4 | 48 | 5 | HPV-*** | ﹢ |

| HPVF80R8P27A | 5 | 80 | 27 | 12.4 | 50 | 6 | ||

| HPVF100R10S32AL | 5 | 100 | 32 | 14.4 | 50 | 8 | ||

| HPVF125R12S40AL | 5 | 125 | 40 | 16.4 | 63 | 10 | ||

| HPVF160R18T40AL | 5 | 160 | 40 | 16.4 | 63 | 12 | ||

| HPVF200R24T60AL | 5 | 200 | 60 | 25.7 | 63 | 12 | ||

| HPVF250R30T60AL | 5 | 250 | 60 | 25.7 | 63 | 15 | ||

| HPVF315R38U60AL | 5 | 315 | 60 | 25.7 | 80 | 18 | ||

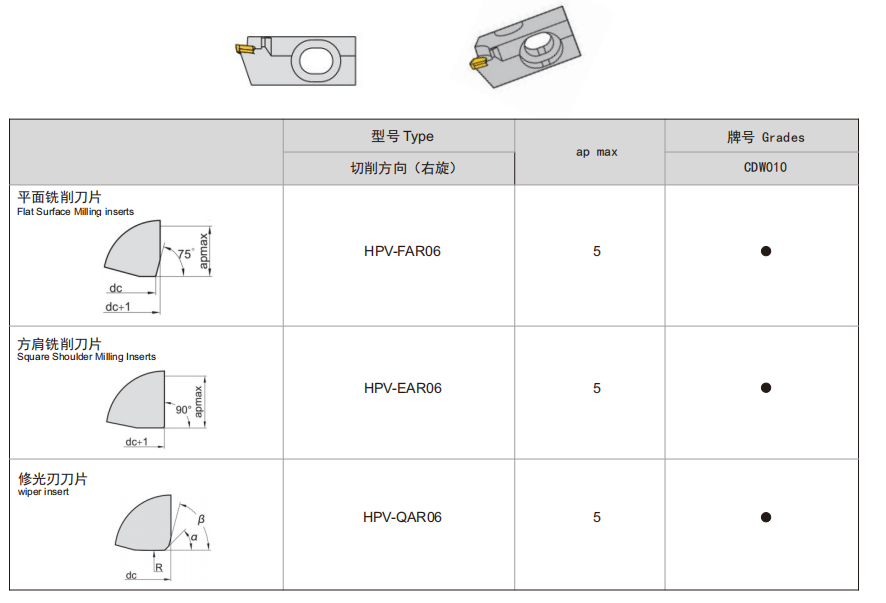

PCD Milling Inserts

Application

Case

| Workpiece: Transmission Housing | Material: Aluminum Alloy ADC12 | Feed Rate: 7000 mm/min |

| Cutting Speed: 2900 m/min | Stock Removal: 1.2mm |

| Tool Diameter: 160mm | Cooling Method: Internal Cooling | |

| Spindle Speed: 5770 r/min | Surface Roughness: Ra 0.3μm | |

| Number of Inserts: 16 | Tool Life: Approximately 17,000 pieces |

Mode:CBN tools Type:Solid CBN Insert,PCBN Insert Application:Hardened Steel

Mode:Milling,Drilling,Reaming Type:PCD Tools,Carbide Tools Application:Aerospace Field

Mode:Turning, Milling, Hole-making Type:PCBN Insert, PCD Tools Application:Auto Parts

Mode:Turning, Milling, Drilling, Boring Type:Crown Drill, PCD Inserts Application:Wind Energy

We are looking for business partners to establish dealerships or become authorized distributors. Join our network and embark on a journey of growth and success with Halnn. You can contact us via market@halnn-group.com or click here .

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.