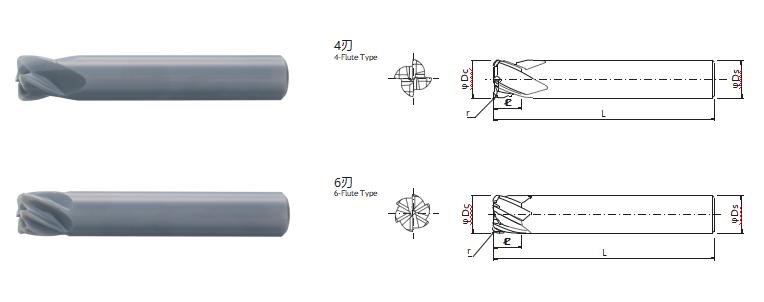

When it comes to machining superalloys like Inconel, Hastelloy, and titanium alloys, precision and efficiency are paramount. Our Ceramic end mills for Super Alloys are specifically designed to tackle the challenges of machining heat-resistant and tough materials. With cutting-edge ceramic technology, these end mills offer unmatched performance, helping you achieve superior surface finishes and reduced machining times.

·Material and Design: Optimized for heat resistance and long-lasting durability.

·Compatibility: Ideal for high-speed machining of heat-resistant materials, including superalloys.

·Specifications: Available in various diameters, geometries, and edge profiles to suit your specific machining needs.

·Tool Diameter Range: From 1mm to 20mm (custom sizes available).

·Cutting Edge Geometry: Tailored for various applications, ensuring optimal performance.

·Customization Options: We offer specific geometries and coatings to meet your unique machining needs.

Mode:Turning, Milling, Drilling, Boring Type:Crown Drill, PCD Inserts Application:Wind Energy

Mode:CBN Inserts Type:BN-S300,BN-S30 Application:Brake Disc/Drum

Mode:RNMN RCMX-V RCMX-Y PCD Type:BN-K1,BN-S20,CDW010 Application:Heavy Machining

Mode: Type: Application:Hydraulic industry

We are looking for business partners to establish dealerships or become authorized distributors. Join our network and embark on a journey of growth and success with Halnn. You can contact us via market@halnn-group.com or click here .

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.