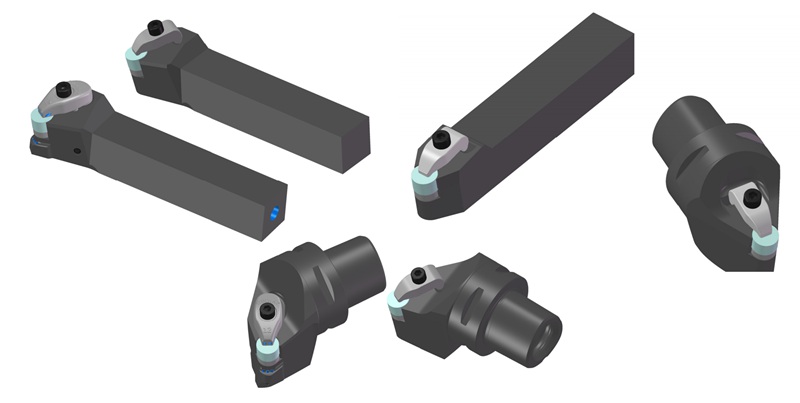

Maximize the performance of your ceramic inserts with our precision-engineered Tool Holders. Designed specifically to support the unique characteristics of ceramic cutting tools, our holders ensure stability, durability, and optimal performance for demanding machining operations.

Built to minimize vibration and maximize stability during machining operations.

Engineered for seamless integration with a wide range of ceramic insert types and geometries, ensuring perfect alignment and support.

Made from high-strength alloys with excellent wear resistance, extending the lifespan of the tool holder even in harsh machining environments.

Provides secure and consistent clamping for ceramic inserts, maintaining precision during high-speed operations and interrupted cuts.

Suitable for a variety of applications, including hard turning, finishing, and interrupted cutting in industries like aerospace, automotive, and mold manufacturing.

1. Enhanced Tool Life: Reduces wear and tear on ceramic inserts by providing a stable machining environment.

2. Improved Productivity: Achieve consistent performance even in high-speed or heavy-load conditions.

3. Cost Efficiency: Durable design reduces the frequency of replacements, lowering overall operational costs.

4. Custom Options: Tailored solutions available for specific machining requirements.

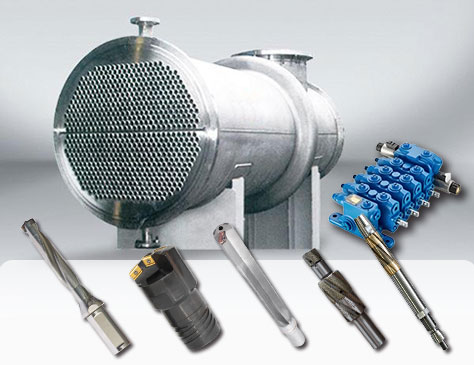

Mode: Type: Application:Hydraulic industry

Mode:Turning, Milling, Hole-making Type:PCBN Insert, PCD Tools Application:Auto Parts

Mode:Turning, Milling, Drilling, Boring Type:Crown Drill, PCD Inserts Application:Wind Energy

Mode:Drilling, Boring, Reaming Type:Gun Drills, Solid Carbide Drill Application:Hole Machining

We are looking for business partners to establish dealerships or become authorized distributors. Join our network and embark on a journey of growth and success with Halnn. You can contact us via market@halnn-group.com or click here .

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.