Halnn offers a wide range of standard products.When standard products are not enough, custom solutions are available to further optimize the drill body and drill tip.

·Diameter range: 3-20mm.

·Depth capability: 2×D–8×D.

·Hole tolerance: H8-H8.

Can be used for a wide range of drilling applications.

Case1

| Workpiece: Valve Body |  |

| Material: Stainless Steel | |

| Hardness: HRC 20 | |

| Tool Diameter: D12 Internal Coolant Drill | |

| Hole Depth: 50 mm | |

| Cutting Speed (Vc): 65.9 mm/min | |

| Spindle Speed (N): 1500 r/min | |

| Feed Rate (F): 225 mm/min | |

| Original Tool Life: 2200 pieces, prone to tool breakage. | |

| Halnn Tool Life: 3500 pieces | |

| Result: Tool life increased by 59%, with stable machining performance. | |

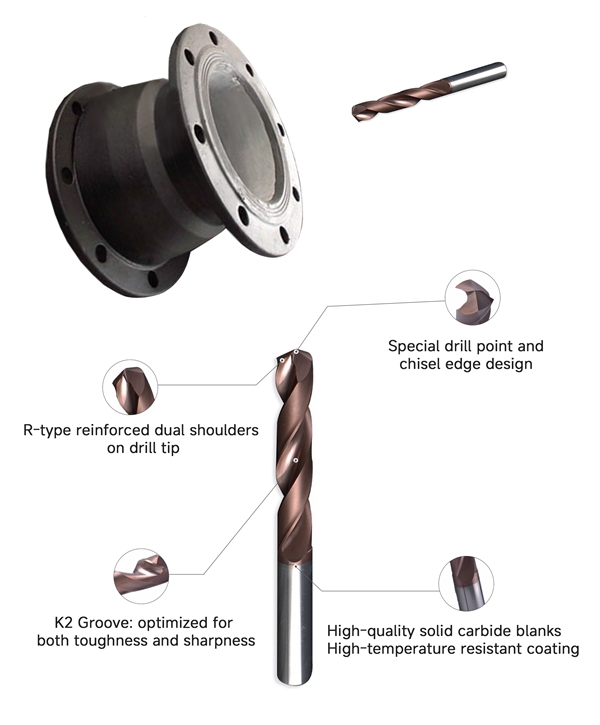

Case2

| Workpiece Material: QT1050 |  |

| Machine Tool: Machining Center | |

| Cooling: External Cooling, Coolant | |

| Machining Position: D17.3, Hole Depth 45mm | |

| Tool Diameter: D17.3 External Cooling Drill Bit | |

| Drilling Depth: 45mm | |

| Cutting Speed (Vc): 50.5 m/min | |

| Spindle Speed (n): 930 r/min | |

| Feed Rate (F): 186 mm/min | |

| Original Tool Life: 70 pieces | |

| Halnn Tool Life: 95 pieces, Stable Cutting | |

| Tool Life Improvement: 35.7%↑ |

Case3

| Workpiece: Wheel Hub Unit |  |

| Workpiece Material: 55# Steel | |

| Workpiece Hardness: HB280 | |

| Machine Tool: Machining Center | |

| Cooling: External Cooling, Coolant | |

| Machining Method: Drilling | |

| Tool Change Standard: Forced Tool Change | |

| Machining Position: Bolt Hole D10.85, Hole Depth 11mm | |

| Result: Original tool life was 1,300 pieces with severe edge chipping. Halnn alloy drill achieved a tool life of 1,700 pieces with no chipping and normal wear, improving tool life by 30% compared to the original tool. | |

Case4

| Industry: Automotive Industry |  |

| Workpiece Name: Turbocharger Housing | |

| Workpiece Material: High-temperature Alloy (1.4837) | |

| Machine Tool: Machining Center | |

| Workpiece Hardness: HB225 | |

| Machining Method: Continuous Machining | |

| Cooling Method: Coolant, Internal Cooling | |

| Tool Change Standard: Forced Tool Change | |

Result: Original tool life was 50 meters with severe edge chipping and wear. Halnn alloy drill achieved a tool life of 65 meters with no chipping and normal wear, increasing tool life by 30%. | |

Mode:Turning, Milling, Hole-making Type:PCBN Insert, PCD Tools Application:Auto Parts

Mode:Turning, Milling, Drilling, Boring Type:Crown Drill, PCD Inserts Application:Wind Energy

Mode:CBN Inserts Type:BN-S300,BN-S30 Application:Brake Disc/Drum

Mode:Milling,Drilling,Reaming Type:PCD Tools,Carbide Tools Application:Aerospace Field

We are looking for business partners to establish dealerships or become authorized distributors. Join our network and embark on a journey of growth and success with Halnn. You can contact us via market@halnn-group.com or click here .

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.