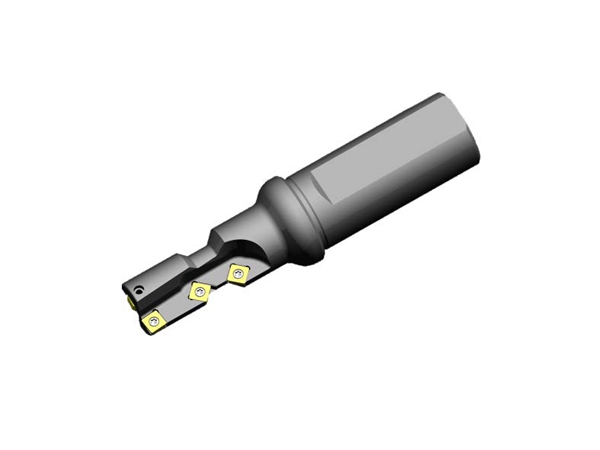

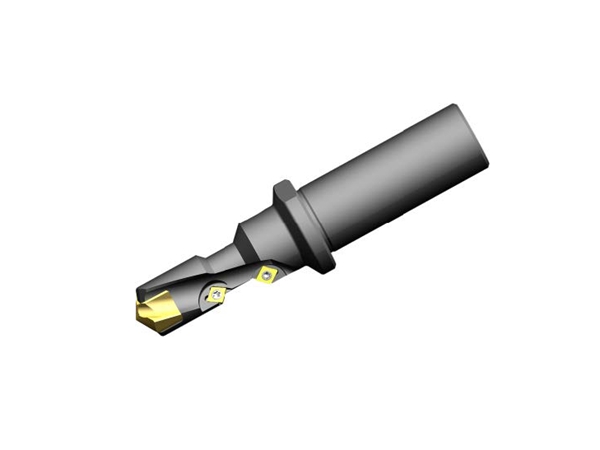

Recommended drills: 7 times or more is recommended

Structure: separate composite crown drill (drill tip + inserts + drill rod), solid crown drill (drill tip + drill rod)

Common diameter: 18-32mm

Whatsapp:+8613271562251

E-mail: halnn@halnn-group.com

|

| Rapid Compound Drill | Indexable Compound Drill | Compound Drill Forward and Reverse Chamfering Drill Rod |

|  |  |

| Compound U-Drill | Crown Drill Forward and Reverse Chamfering Drill Rod | Drill and Precision Boring Rod |

|  |  |

| Quick Change Head Drill Rod | Quick Change Drill Rod | Tool Holder Large Diameter U-Drill |

|  |  |

| Anti-Vibration Sleeved Drill | Centering Reamer Drill | Drill and Precision Boring |

|  |  |

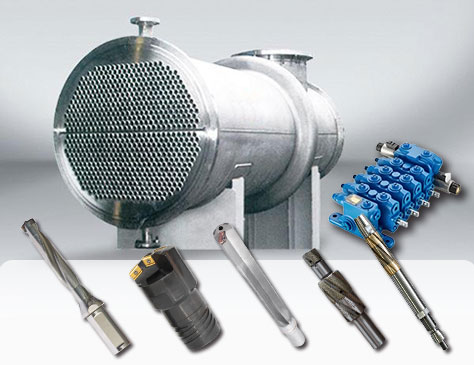

Application

Cases

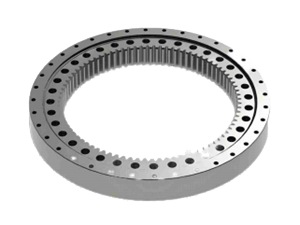

| Parts: Slewing Bearing | Other Brand | Halnn | |

| Material: 50Mn | Cutting Speed Vc (mm/min) | 83 | 83 |

| Drill Rod: D862-181T3WD25 | Spindle Speed n (r/min) | 1400 | 1400 |

| Drill Tip: D862-1890HZ HP9052 | Feed Rate f (mm/rev) | 0.2 | 0.2 |

| Diameter ɸ (mm) | 60 | 60 |

Drilling Depth (mm) | 60 | 60 | |

| Machining Life (m) | 23 | 41 | |

| Life Improvement | 100% | 178% |

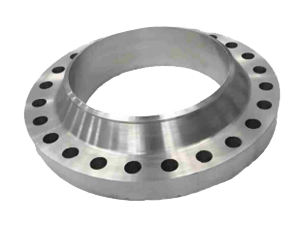

| Parts: Flange | Other Brand | Halnn | |

| Material: 42CrMo | Cutting Speed Vc (mm/min) | 70 | 70 |

| Drill Rod: D861-150T5WD20 | Spindle Speed n (r/min) | 1450 | 1450 |

| Drill Tip: D861-1550HZ HP9030 | Feed Rate f (mm/rev) | 0.2 | 0.2 |

| Diameter ɸ (mm) | 15.5 | 15.5 |

| Drilling Depth (mm) | 60 | 60 | |

| Machining Life (m) | 23 | 41 | |

| Life Improvement | 100% | 142% |

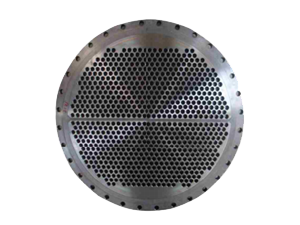

| Parts: Tube Sheet | Other Brand | Halnn | |

| Material: Q235B | Cutting Speed Vc (mm/min) | 96 | 96 |

| Drill Rod: D862-190T5WD25 | Spindle Speed n (r/min) | 1350 | 1350 |

| Drill Tip: D861-1930HZ HP9050 | Feed Rate f (mm/rev) | 0.3 | 0.3 |

| Diameter ɸ (mm) | 22.6 | 22.6 |

| Drilling Depth (mm) | 60 | 60 | |

| Machining Life (m) | 42 | 60 | |

| Life Improvement | 100% | 178% |

Mode:Drilling, Boring, Reaming Type:Gun Drills, Solid Carbide Drill Application:Hole Machining

Mode:Turning, Milling, Hole-making Type:PCBN Insert, PCD Tools Application:Auto Parts

Mode:Turning, Milling, Drilling, Boring Type:Crown Drill, PCD Inserts Application:Wind Energy

Mode:CBN Inserts Type:BN-S300,BN-S30 Application:Brake Disc/Drum

We are looking for business partners to establish dealerships or become authorized distributors. Join our network and embark on a journey of growth and success with Halnn. You can contact us via market@halnn-group.com or click here .

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.