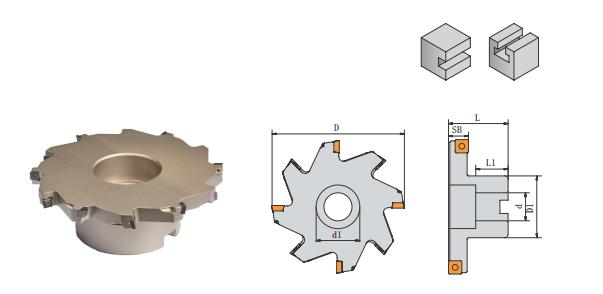

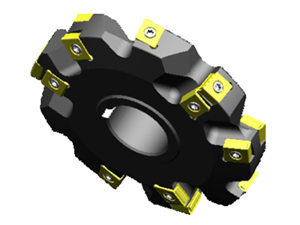

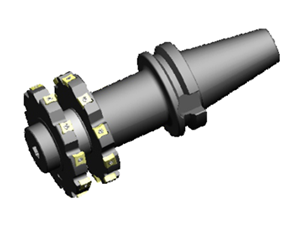

The three-edge milling cutter is a high-efficiency, multifunctional tool designed for milling operations. Its unique three-edge structure—comprising a primary cutting edge on the cylindrical surface and secondary cutting edges on both end faces—ensures excellent performance in groove milling, step surfaces, and side machining. Manufactured from premium materials such as high-speed steel and carbide, and enhanced through precision heat treatment, this cutter guarantees sharp edges, smooth cutting, and extended tool life, making it ideal for various machining applications.

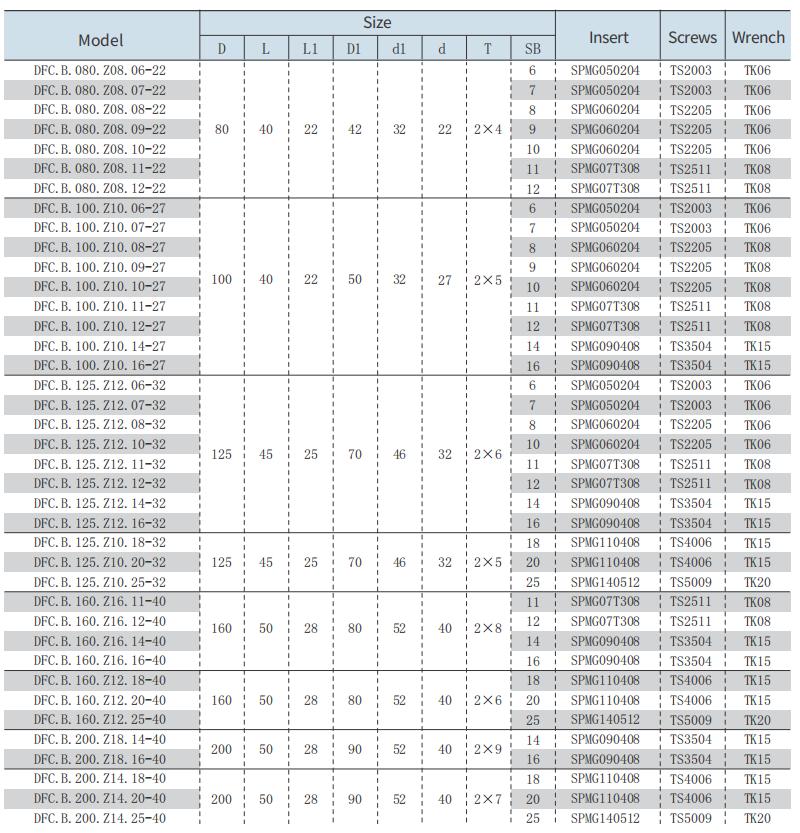

DFC Slot Milling Cutter

High speed three-edge milling cutter specifications

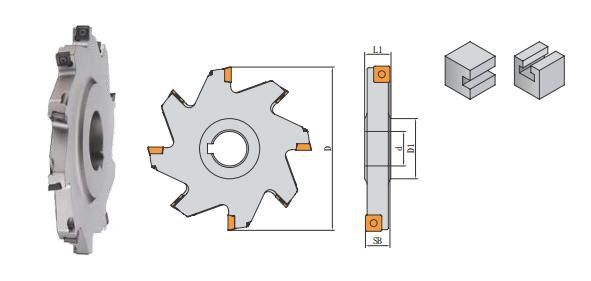

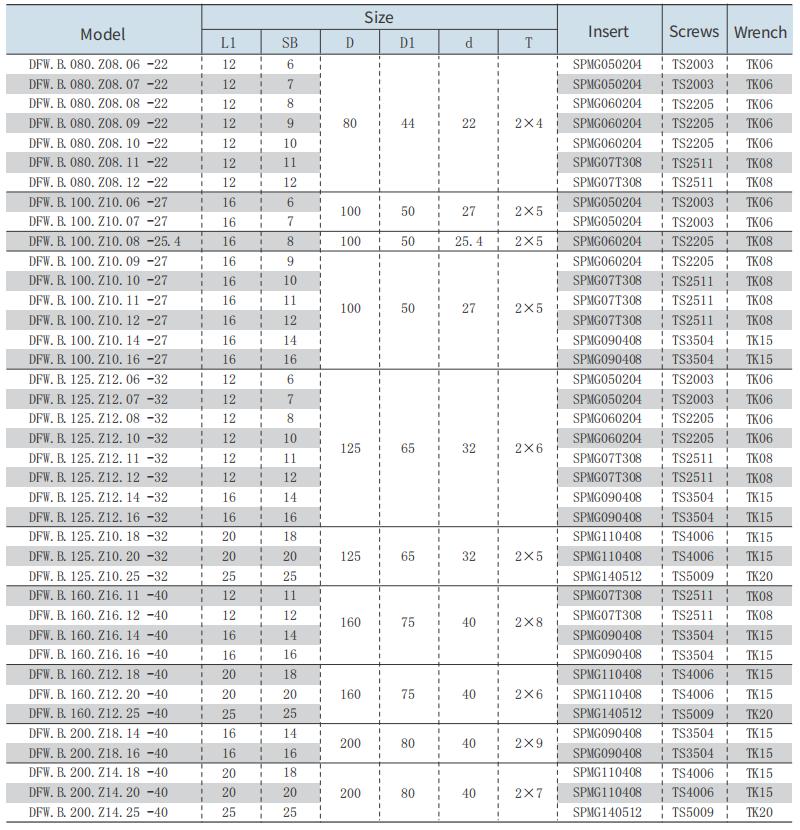

DFW Slot Milling Cutter

High speed three-edge milling cutter specifications

Custom Three-edge Milling Cutter

|  |  |

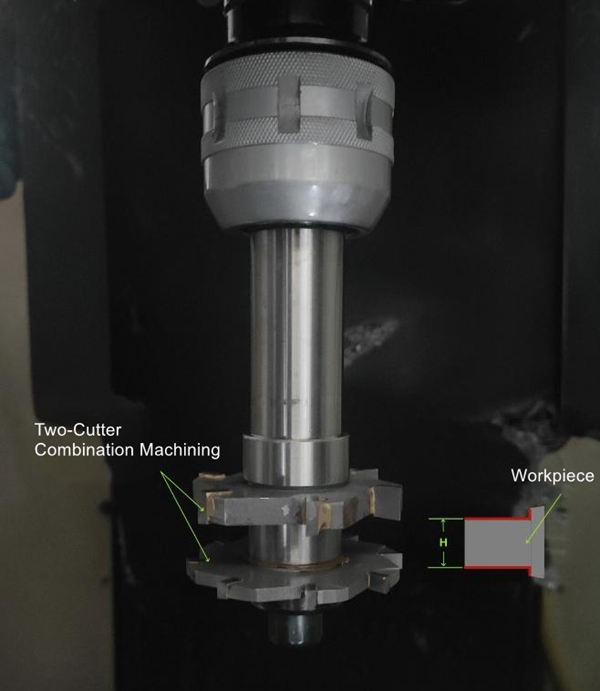

Multi-blade three-edge milling cutter combination processing:

Mode:Drilling, Boring, Reaming Type:Gun Drills, Solid Carbide Drill Application:Hole Machining

Mode: Type: Application:Hydraulic industry

Mode:CBN Inserts Type:BN-S300,BN-S30 Application:Brake Disc/Drum

Mode:Turning, Milling, Drilling, Boring Type:Crown Drill, PCD Inserts Application:Wind Energy

We are looking for business partners to establish dealerships or become authorized distributors. Join our network and embark on a journey of growth and success with Halnn. You can contact us via market@halnn-group.com or click here .

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.