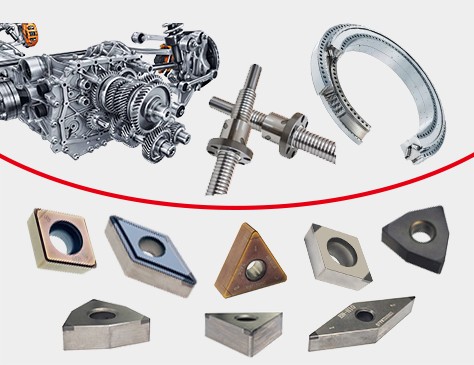

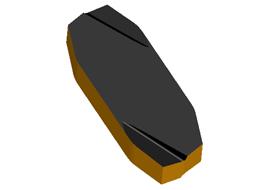

Halnn’s peeling inserts are precision-engineered to meet the demands of heavy-duty machining. Designed for durability and accuracy, these inserts ensure exceptional performance, even in challenging conditions, making them a reliable choice for industries requiring high-quality peeling tools.

Halnn Peeling Insert Types

| Peeling Inserts | |||||||

|

|

|

|

|  |  |  |

YNMX2518173L | YNUX181215SL-S | YNMX381227 | YNMF3613 | YNMF2007 | YNMX1207L | YNMX1207R | YNMX2006L |

| Order No. | Dimension(mm) | Grade | |||

| L1 | L2 | s | HL7650 | HL7659 | |

| YNMF2007 | 30.6 | 12 | 7.8 | ● | ○ |

YNMF3613 | 36.5 | 23.6 | 12.3 | ● | ○ |

| YNUX181215SL-S | 36.7 | 18 | 12 | ● | ○ |

| YNMX1207L | 30.7 | 17.2 | 7.5 | ● | ○ |

| YNMX1207R | 30.7 | 17.2 | 7.5 | ● | ○ |

| YNMX2518173L | 62 | 25 | 18 | ● | ○ |

| YNMX2006L | 20.5 | 8 | 5.75 | ● | ○ |

| YNMX381227 | 38.2 | 22.3 | 12 | ● | ○ |

Product Range

Halnn offers a comprehensive range of peeling inserts to meet diverse machining needs:

·Standard Inserts: Pre-engineered for common applications.

·Customized Inserts: Tailored designs to meet unique machining challenges, including specific sizes, edge geometries, and material compositions.

Bar peeling inserts are highly effective in removing surface layers from various materials, including carbon steel, alloy steel, stainless steel, aluminum alloys, and copper alloys. They are widely used across the following industries:

·Steel Industry: Removes oxide scale and surface defects from billets, ingots, and bars, ensuring better quality for subsequent processing.

·Non-Ferrous Metals: Enhances the surface quality and precision of aluminum, copper, and titanium bars.

·Automotive Manufacturing: Processes precision bars for critical components such as drive shafts and piston rods.

·Aerospace Industry: Produces high-precision, high-performance bars for aerospace components.

·Machinery Manufacturing: Ensures precise machining of shafts and other key mechanical components.

Mode:Turning, Milling, Drilling, Boring Type:Crown Drill, PCD Inserts Application:Wind Energy

Mode:CBN tools Type:Solid CBN Insert,PCBN Insert Application:Hardened Steel

Mode:Solid CBN Insert Type:BN-K1,BN-S20 Application:Wear Parts

Mode:Turning, Milling, Hole-making Type:PCBN Insert, PCD Tools Application:Auto Parts

We are looking for business partners to establish dealerships or become authorized distributors. Join our network and embark on a journey of growth and success with Halnn. You can contact us via market@halnn-group.com or click here .

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.

For all inquiries fill in the form below to send us a brief message,and we will get back to you as soon as possible.